Facade Fabrication Machinery for Aluminium

Façade Machinery for Aluminium – Precision, Strength and Efficiency in Modern Façade Construction

Aluminium in Façade Construction – The Material of the Future

Aluminium is now the dominant material in modern façade systems. Its combination of light weight, stability, corrosion resistance, and design flexibility makes it ideal for ambitious architectural projects.

To turn architectural visions into reality, precise façade machinery for aluminium is essential—machines capable of cutting, milling, drilling, and joining profiles with absolute accuracy.

Evomatec specializes in this technology, offering advanced aluminium profile processing machines that guarantee maximum precision, speed, and reliability.

CNC Profile Machining Centers – The Heart of Aluminium Façade Production

Precision Through CNC Technology

A CNC profile machining center for aluminium is the foundation of professional façade fabrication. These machines perform all essential operations—from milling and drilling to marking—with exceptional accuracy.

Evomatec machining centers such as EVOG800, EVOGXS4, and EVOAIIC feature servo-driven axes, digital CNC control systems, and automatic tool changers for seamless workflows.

With machining angles from −90° to +90°, automatic profile clamping, and CAD/CAM software integration, they deliver flawless results—even for complex aluminium profiles used in curtain walls, post-and-beam systems, and structural glazing applications.

Large-Format Processing with EVO XL ACP

For large aluminium composite panels, Evomatec’s EVO XL ACP offers a high-precision 3-axis CNC solution for cutting, milling, and drilling ACP sheets.

With a working range up to 7000 × 1600 mm, it is ideal for producing façade cladding, signage panels, and architectural aluminium composite elements.

Bar Machining Centers – Efficiency for Long Aluminium Profiles

In façade manufacturing, long profiles up to six meters must be processed with high precision.

Evomatec’s bar machining centers handle these operations fully automatically, combining sawing, milling, drilling, and marking in a single pass.

Servo drives and intelligent clamping systems enable continuous processing of multiple profiles without manual intervention—boosting both productivity and accuracy.

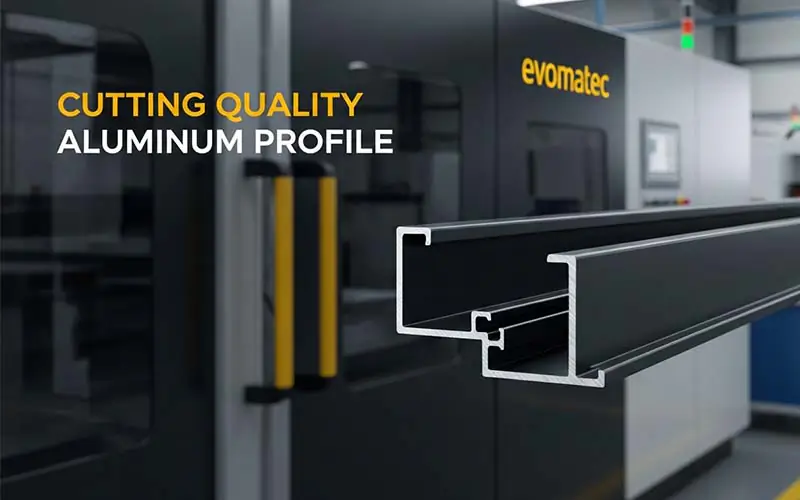

Cutting and Miter Saws – Accurate Cuts for Façade Systems

Precise Cutting for Aluminium Profiles

In aluminium frame and support processing, a cutting saw for aluminium is indispensable.

Evomatec’s EVOCUT 300 features stable carbide blades and adjustable miter angles to ensure perfect, burr-free cuts.

Its vibration-free operation and solid frame construction guarantee clean cut surfaces—essential for stable façade structures.

Double Miter Saws for Aluminium

For façade fabrication, precise miters are crucial.

Evomatec’s EVOG X and EVOM II 500 are automatic double miter saws with servo-controlled heads, offering precise cutting between 45° and 90°, automatic length positioning up to 6000 mm, and touchscreen digital control.

They are the ideal solution for high-volume production where accuracy and repeatability are key.

Milling Machines – Copy and Notching Mills for Aluminium Façades

Copy Routers for Aluminium Profiles

Copy milling machines are used in façade manufacturing to produce openings, slots, and hardware recesses in aluminium profiles.

Evomatec copy routers operate on three sides simultaneously and provide adjustable depth and feed control. Pneumatic clamping ensures secure profile positioning throughout the process.

This guarantees precise machining for screw joints, sealing grooves, and system connections.

Notching Mills – Precision at Connection Points

Notching machines such as Evomatec EVOP IV perform accurate end machining on profile edges.

They mill notches, grooves, and fitting areas for exact assembly—crucial in curtain wall and post-and-beam constructions.

Corner Crimping Presses – Stability in Aluminium Frame Construction

In façade production, frame and carrier profiles must be securely joined.

Evomatec’s EVOA I corner crimping press uses hydraulic pressure and automatic centering to create durable and highly accurate joints.

Adjustable crimping blades and profile-dependent centering enable reliable pressing even on large or complex profiles.

This technology ensures long-lasting, form-fit connections—vital for structural integrity and tightness in façade systems.

Glazing Bead Saws – Perfect Cuts for Glass Retaining Beads

Modern aluminium façades use glazing beads to secure glass panels.

Evomatec glazing bead saws deliver smooth, repeatable miter cuts and burr-free surfaces.

Their stable construction and precision guidance make them ideal for continuous industrial use.

Automation and Industry 4.0 in Façade Manufacturing

Digital Process Integration

Evomatec integrates advanced CNC control, networking, and process software into its machines.

This allows complete digitalization of production—from CAD design to real machining.

Machines communicate, exchange data, and monitor all parameters in real time.

Advantages of Smart Manufacturing

– Higher precision through digital profile measurement

– Automatic tool identification

– Efficient production planning and traceability

– Reduced waste and energy consumption

Thus, aluminium façade manufacturing becomes smarter, faster, and more sustainable.

Quality and Service – The Evomatec Standard

Every Evomatec machine is built according to European safety and quality regulations and CE certified.

Comprehensive services include:

– Operator and technician training

– Online installation via video conference or on-site support

– Express spare-part delivery during warranty

– Technical assistance from experienced engineers

Evomatec machines are used worldwide—from small metal workshops to large industrial façade production lines.

Sustainability in Aluminium Façade Construction

Sustainability is now a key factor in the construction industry. Aluminium is 100% recyclable, and Evomatec designs machines that minimize energy use and material waste.

Precision CNC control, intelligent feed systems, and efficient cooling technology significantly reduce production scrap and operating costs.

In doing so, Evomatec actively supports environmentally friendly and resource-efficient façade production.

Conclusion

Façade machinery for aluminium forms the foundation of modern architecture, combining technology, design, and precision to create durable and energy-efficient building envelopes.

With state-of-the-art CNC machining centers, double miter saws, copy routers, crimping presses, and automation solutions, Evomatec provides everything needed to elevate aluminium façade processing to the next level.

Those who strive for maximum precision, productivity, and reliability in aluminium façade manufacturing choose Evomatec – the partner for sustainable, high-performance façade production.

English

English

German

German

French

French

Spanish

Spanish

Portuguese

Portuguese

Italian

Italian

Polish

Polish

Turkish

Turkish

Romanian

Romanian

Greek

Greek

Bulgarian

Bulgarian

Russian

Russian

Arabic

Arabic

Hindi

Hindi