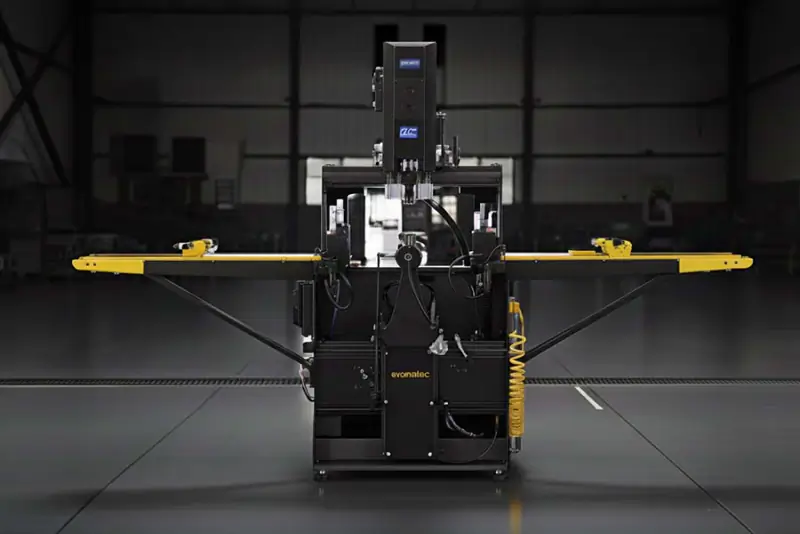

Copy router

Copy Router – Precise Profile Machining for Professional Window, Door and Façade Production

A copy router is an indispensable tool in modern profile machining for windows, doors and façades whenever precise cut-outs, slots, hardware holes and special contours in aluminium and plastic profiles are required. It bridges the gap between traditional manual work and highly automated CNC machining centres and is therefore of central importance in both craft businesses and industrial production. Wherever profiles must be machined in a repeatable, safe and standards-compliant way, the copy router ensures accuracy, repeatability and process reliability.

By using a copy routing machine in a targeted manner, both single parts and series can be produced economically. At the same time, all requirements regarding CE-compliant machine safety, occupational safety and quality assurance must be fulfilled. This is where the experience of specialised providers comes into play: Thanks to Evomatec’s many years of project experience with a large number of customer installations, inspections and tests can be organised in such a way that they are always carried out with the utmost care in terms of quality, process flows and CE-compliant safety.

Modern companies in window production, door manufacturing and façade construction are under increasing competitive pressure. They must guarantee short delivery times, high quality and verifiability within the framework of standards and regulations. In this environment, the copy router is a highly relevant production asset that enables flexible, yet very robust and reproducible profile machining.

Fundamentals of the Copy Router

The copy router belongs to the family of milling machines and is specially designed to transfer contours from a template or pattern onto a workpiece. In most cases, these are aluminium or plastic profiles as used in window, door and façade production.

Definition and distinction from a conventional milling machine

While a conventional milling machine is often freely programmable or manually adjustable, the copy router primarily works with templates. Via mechanical systems or tracing devices, feeler pins or stops follow a template, and the milling spindle transfers the contour onto the profile.

A copy routing machine therefore differs significantly from pure sawing machines, drilling machines or standard milling machines:

It is precisely tailored to typical machining tasks on profile geometry in window and door production.

It enables fast repetition of identical cut-outs on a wide variety of profiles.

It is suitable for serial production as well as for individual special solutions.

The objective is always safe, repeatable and economical machining of profiles without having to program every single contour from scratch or laboriously mark it out by hand.

Historical development of the copy router

The copy router has evolved significantly in the course of the industrialisation of window and façade construction. Early copy routers operated purely mechanically: a fixed template, a tracing pin and a milling spindle – often, not much more was needed. With increasing demands on accuracy, occupational safety and compliance with standards, the following were added:

improved clamping devices

more powerful spindles

more precise guides

pneumatic and hydraulic drives

optimised safety hoods and protective devices

With the advent of CNC technology, machining centres were developed that could map copying functions digitally. Nevertheless, the classic copy router remained an important element in many companies because it is particularly economical, robust and easy to operate. Even today, many professional window manufacturers deliberately rely on a high-quality copy routing machine as a complement to complex CNC systems.

Design and technology of a copy routing machine

A professional copy router consists of several assemblies that are precisely matched to each other. Their quality has a decisive influence on the accuracy, process reliability and service life of the machine.

Machine base and construction

The base frame of a copy routing machine is usually designed as a heavy, torsion-resistant machine bed. It absorbs all forces that occur during milling. A solid construction is crucial to:

minimise vibration

ensure dimensional accuracy

guarantee long service life of guides and spindles

The use of high-quality materials and careful workmanship ensure that the machine operates reliably even under continuous industrial conditions. In designing its own systems, Evomatec places great emphasis on ensuring that the machine base is tailored to the specific requirements of profile machining in window production.

Clamping systems for profiles

The clamping technology is a central feature of every copy router. Only profiles that are clamped safely and repeatably can be machined precisely. Typical clamping systems are:

pneumatic clamping cylinders for fast and powerful clamping

mechanical clamping levers or eccentrics for simple set-up work

combined clamping systems to securely hold different profile geometries

Especially in companies that process aluminium and plastic profiles from different system suppliers, flexible clamping technology is a key advantage. With suitable clamping jaws, stops and supports, profiles with different multi-chamber geometries can be reliably fixed.

Milling spindle and tools

The heart of the copy routing machine is the milling spindle. It determines which tools can be used and how powerful the machine is in practice. Important parameters are:

speed range of the spindle

tool interface

motor power

quality of the bearings

In profile machining, solid carbide and HSS cutters as well as special hardware cutters with defined cutting edges are frequently used. A well-matched combination of tool quality, cutting speed and feed rate ensures:

clean edges

low burr formation

reduced rework

long tool life

Careful tool selection and regular inspection are important not only for economic reasons but also to ensure safe, predictable machining in accordance with CE requirements.

Copy templates, stops and tracing systems

The typical feature of a copy router is working with templates and stops. The operator defines a template along which the tracing pin is guided. The milling spindle follows this contour in relation to the transmission ratio of the machine.

Modern copy routers offer:

flexible templates that can be changed quickly

adjustable stops for different profile positions

repeatable fixing of the template to ensure consistent accuracy

To prevent errors from being produced in series, correct setting of the template is especially important. It is therefore advisable to check the system regularly. Thanks to Evomatec’s many years of experience from window production projects, inspections can be planned in such a way that both the functionality of the copy router and compliance with the relevant safety standards are reliably verified.

Functioning of the copy router in detail

The way a copy routing machine works is both simple and demanding: simple in terms of operating logic, demanding in terms of accuracy, set-up work and process reliability.

Manual, semi-automatic and pneumatic processes

In many companies, copy routers with manual operation are used:

The operator clamps the profile, moves the milling unit into position, activates the spindle and guides the unit along the template. Pneumatic infeed movements and automatic clamping systems facilitate the workflow and increase repeatability.

Semi-automatic functions such as automatically controlled infeed motion or defined return movements reduce sources of error and increase productivity. This is precisely where the value of a well-designed machine becomes apparent, consistently tailored to typical machining tasks in window production.

Setting stops and templates

Before starting serial production, stops, templates and infeed paths must be set with great care. Typical steps include:

selection of the appropriate template for the required hardware or cut-out

exact positioning of the template in relation to the profile

setting stops for length and position

trial milling on a sample profile

release for serial production after quality inspection

In many companies, it is common practice to carry out these set-up processes in accordance with defined work instructions. If desired, Evomatec supports businesses in establishing and documenting such standardised procedures in connection with a copy router, so that quality and safety are permanently ensured.

Fields of application and industries

The copy routing machine is used in several industries, with its main focus clearly on profile machining for window, door and façade constructions.

Window production in aluminium and plastic

In window production, the copy router is particularly important when it comes to:

hardware drilling

slots for gearboxes and handle drives

water drainage openings

ventilation openings

special cut-outs for custom hardware

Aluminium and plastic windows consist of complex multi-chamber profiles. Precise machining of these profiles is crucial for the function, tightness and durability of the finished window. Here, the copy router for aluminium profiles and the copy router for plastic profiles provide the necessary flexibility and accuracy.

Door production and façade construction

In door manufacturing, copy routers are used for milling lock cases, hinges, strike plates and special fittings. In façade construction, copy routers are used on mullion-transom profiles, segmented façades and special constructions when cut-outs are needed for connecting elements, brackets or service lines.

The same applies here: professional profile machining with a high-quality copy routing machine is a prerequisite for meeting structural requirements, sealing concepts and visual expectations alike.

Metalworking and plastics engineering

In addition to classic window and façade construction, copy routers are used in:

general metalworking shops

workshops for technical plastic components

companies producing prototypes and small series

Wherever recurring cut-outs based on a template must be machined into profiles or components, the copy router is an efficient tool.

Practical examples from everyday operations

A typical practical example in window production: A company produces several dozen windows per day from aluminium profiles of different systems. A flexible yet robust solution is required for the hardware machining.

With a copy routing machine, a suitable template is created for each profile, containing all required holes and slots for the hardware. The machine operator:

clamps the profile

positions it against a reference stop

guides the milling unit along the template

This produces a large number of identical cut-outs in a short time without having to reprogram each window.

Another example: In door production, custom solutions are required for project doors with special fittings. The copy router makes it possible to manufacture even small batch sizes economically by simply creating a dedicated template for these special fittings. In situations like these, the flexibility of the copy router proves superior to purely series-oriented machines.

In many companies, copy routers are regularly inspected by external specialists. Evomatec draws on its extensive experience from numerous customer projects to ensure that such inspections are consistently focused on process reliability, dimensional accuracy and compliance with the relevant CE safety requirements.

Quality, CE conformity and occupational safety

In addition to productivity and precision, CE-compliant safety plays a central in the evaluation of a copy routing machine.

Protective devices and safety concepts

A contemporary safety concept includes:

appropriate safety hoods and covers

fail-safe design of operating elements

clearly traceable emergency stop functions

clear markings and warnings

adequate operating instructions

Only when these components are sensibly coordinated can the operator reliably fulfil their obligations under the Machinery Directive. Evomatec supports companies in evaluating these aspects and, through strictly structured testing processes, ensures that inspections are carried out with the highest degree of care regarding quality, documentation and CE conformity.

Risk assessment and documentation

A copy router is a powerful working tool. Therefore, careful risk assessment is indispensable. This includes:

analysis of potential hazards during milling, clamping and set-up

assessment of residual risks

definition of suitable protective measures

training of operating personnel

The results must be documented and updated regularly. Based on extensive practical experience from numerous projects, Evomatec can help companies to set up, review and improve these processes in a practical way.

Quality assurance in profile machining

Quality assurance means more than just meeting dimensional tolerances. Issues such as burr formation, surface quality, tolerances and reproducibility also play a major.

Regular inspections of the copy routing machine, the clamping technology, the tools and the templates ensure that the required standards are consistently met. Thanks to its many years of experience in profile machining, Evomatec knows what is important in such inspections and how to structure them so that they are both technically sound and compliant with standards and CE requirements.

Advantages of the copy router in professional production

The copy router offers a number of advantages that are particularly valued in window, door and façade production.

High flexibility for profiles and hardware

The ability to use dedicated templates for different profiles and hardware makes the copy routing machine extremely flexible. New requirements in project business can be implemented quickly by creating suitable templates.

Economical serial and single-part production

Compared to complex CNC programs, setting up a copy router is often considerably faster. Especially for medium batch sizes or frequently changing profiles, this is a decisive productivity advantage.

Robust design and easy operation

Many users appreciate the robustness and intuitive operation of the copy router. An experienced operator can achieve very high-quality results in a short time.

Limitations and boundaries of the copy router

Despite its advantages, the copy routing machine also has its limits.

Limited level of automation

Compared to a full-scale CNC machining centre, the level of automation is lower. While recurring machining patterns can be mapped very effectively, highly complex free-form contours or fully automated machining sequences are more the domain of CNC centres.

Dependence on templates

Every new contour requires a corresponding template. Although this is simple and robust, it does require coordinated template management and clear documentation.

Operator dependency

The quality of the result largely depends on the operator’s experience. A good level of training and clear work instructions are therefore essential. Where required, Evomatec supports customers in training operators and establishing practical standards so that the copy router can fully realise its potential.

Costs, cost-effectiveness and investment planning

Investment in a copy router must be economically justified. The overall service life is the decisive factor.

Acquisition costs

Compared to complex CNC machining centres, the acquisition costs for a copy router are usually significantly lower. However, the level of investment can vary depending on equipment, clamping technology, spindle power and degree of automation.

Operating and maintenance costs

The main cost factors in operation are:

energy consumption

tooling costs

maintenance and spare parts

training and qualification of personnel

Well-designed machines are characterised by a long service life and moderate maintenance costs. Regular inspections help to avoid unplanned downtime. Through Evomatec’s systematic approach to maintenance and inspection concepts, companies can safeguard machine availability while maintaining CE-compliant safety at a high level.

Cost-effectiveness analysis

In cost-effectiveness analyses, the copy router is often compared with other investment options, such as CNC machining centres.

The following questions are crucial:

What is the annual machining volume?

How frequently do profiles and hardware variants change?

What requirements does the market place on flexibility and delivery times?

For many medium-sized companies, a combination of a robust copy routing machine and selected CNC systems is the most economical solution.

Maintenance, service and inspections

To ensure the long-term performance of the copy router, a structured maintenance and service concept is essential.

Regular care and cleaning

A clean machine condition is the basis for precision and longevity. This includes:

regular removal of chips and dust

inspection and relubrication of guides

inspection of the clamping devices

visual checks of cables, hoses and safety guards

Preventive maintenance

Preventive maintenance means detecting and correcting wear in good time before failures occur. Measurement protocols, checklists and regular inspection intervals can be used for this purpose.

In many customer projects, Evomatec combines technical expertise with clearly structured inspection procedures. This ensures that maintenance and inspections are not only performed formally but also deliver high-quality results and take all aspects of CE-compliant safety into account.

Retrofit and modernisation

Older copy routers can often be brought up to the latest state of the art through sensible retrofits, for example by:

improved safety guards

new clamping systems

optimised control elements

Experience from numerous modernisation projects helps in assessing which retrofits are technically and economically viable. Evomatec supports companies in the decision-making, planning and implementation of such measures.

Future prospects of the copy router

Even though CNC machining centres are becoming ever more powerful, the copy router will continue to play an important.

Digitalisation of processes

Set-up data, template information and inspection records are increasingly being managed digitally. The copy router can be integrated into such digital process chains, for example by systematically cataloguing templates and linking them with digital drawings.

Combination with CNC technology

In many production lines, copy routers and CNC machines work hand in hand. CNC centres take over complex machining operations, while the copy routing machine carries out flexible or less frequently required cut-outs economically.

Increasing requirements for safety and quality

Requirements for documented quality and safety will continue to rise. Companies must be able to prove that their machines – including copy routers – are operated safely and inspected regularly.

Evomatec sees a key task here in supporting companies so that inspection and testing processes are structured, traceable and CE-compliant. Through close cooperation with numerous companies in window, door and façade production, Evomatec is able to contribute its experience to integrate copy routers optimally into modern production concepts.

Conclusion: Copy router as key technology in profile machining

The copy router is far more than a simple milling machine. It is a central tool for professional profile machining in window, door and façade production.

Its strengths lie in:

high flexibility for profile and hardware variants

cost-effective machining of small and medium batch sizes

robust design and easy operation

the ability to implement custom solutions efficiently

Anyone planning the purchase, modernisation or inspection of a copy router should take a holistic view of technology, cost-effectiveness, CE-compliant safety and quality assurance. Evomatec combines technical expertise with extensive project experience to ensure that copy routers are used reliably, safely and profitably in practice.

Thanks to a systematic approach based on many successfully completed customer projects, Evomatec can ensure that inspections and assessments of copy routers are carried out with the highest level of accuracy, technical diligence and strict alignment with CE conformity requirements. In this way, the copy router becomes a long-term safe, high-performance and economical component of modern production lines.

FAQ on copy routers

Question 1: What is a copy router mainly used for in window production?

A copy router is primarily used in window production for machining aluminium and plastic profiles. Typical tasks include milling slots for hardware, water drainage openings, ventilation openings and special cut-outs that are precisely adapted to the respective profile geometry. By working with templates, these machining operations can be carried out with repeatable accuracy and in an economical way.

Question 2: When is a copy router worthwhile compared to a CNC machining centre?

A copy routing machine is particularly worthwhile when many different profiles with varying hardware configurations must be machined and medium batch sizes are predominant. Set-up time is often shorter than with complex CNC programs, and templates can be modified relatively quickly. For highly complex machining operations and fully automated production lines, a CNC machining centre remains advantageous, but in many companies the combination of both technologies is ideal.

Question 3: What does CE conformity play in copy routers?

CE conformity is of central importance for a copy router because it is a powerful machine with rotating tools. Protective devices, operating concept, emergency stop features and documentation must meet legal requirements. Regular inspections and a structured risk assessment are necessary to ensure the safety of operators and the business over the long term. Thanks to extensive practical experience, Evomatec can design inspections in such a way that they not only fulfil formal requirements but also sustainably improve the actual safety and quality of the machine.

Question 4: Which factors determine the machining quality achieved with a copy router?

Machining quality depends on several factors: stability of the machine base, precision of the clamping technology, quality of the milling spindle, condition of the tools and accuracy of the templates. Equally important are careful set-up, clearly defined work instructions and well-trained personnel. Regular inspection of the machine by experienced specialists ensures that all components interact optimally and that the required tolerances are reliably maintained.

Question 5: Can older copy routers be modernised to meet current safety standards?

In many cases, older copy routers can be upgraded to meet current requirements by retrofitting improved safety guards, modern clamping systems or optimised control elements. Which measures make sense depends on the individual condition of the machine and the operational requirements. Evomatec supports companies in analysing and planning such modernisation projects and ensures that technical improvements and CE-compliant safety are sensibly combined.

Request your free consultation for your copy router projects atinfo@evomatec.de

English

English

German

German

French

French

Spanish

Spanish

Portuguese

Portuguese

Italian

Italian

Polish

Polish

Turkish

Turkish

Romanian

Romanian

Greek

Greek

Bulgarian

Bulgarian

Russian

Russian

Arabic

Arabic

Hindi

Hindi