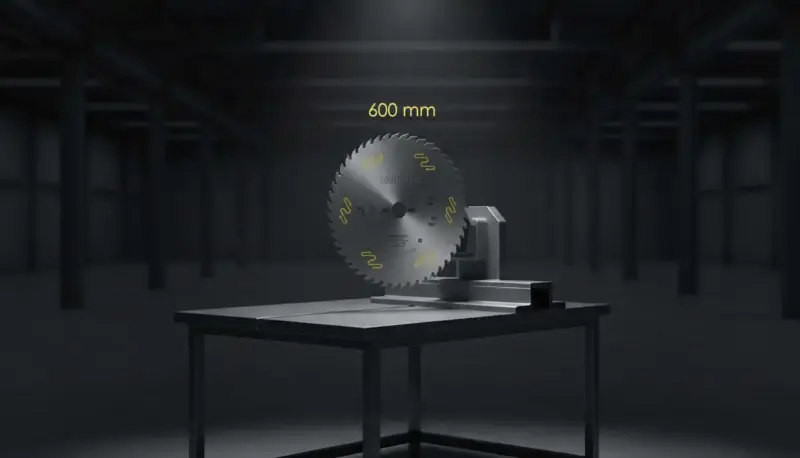

CIRCULAR SAW BLADES FOR ALUMINIUM PROFILES WITH 600 MM EVO SAW A600

Circular Saw Blade for Aluminium Profiles with Ø 600 mm and Negatively Set Teeth EVO SAW A600

Industrial precision for aluminium, aluminium profiles, and solid material with outstanding cutting quality

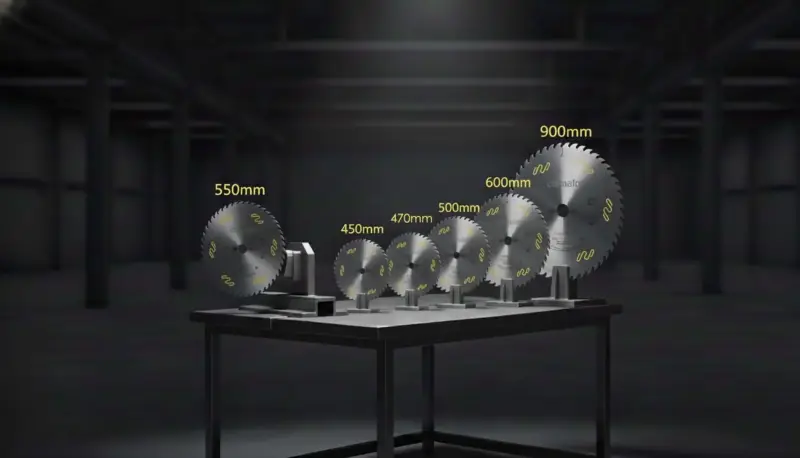

In professional aluminium processing, not only the machines are crucial for success, but also the quality of the tool. A state-of-the-art circular saw blade for aluminium must run consistently stable even at high volumes, provide burr-free cuts, and remain precise over long operating hours. The EVOMATEC EVO SAW A600 was specifically developed for these demanding requirements in series production. The circular saw blade for aluminium profiles EVO SAW A600 has a diameter of Ø 600 mm and is equipped with 120 negatively set teeth. This special tooth geometry ensures a controlled, smooth cut, particularly optimized for aluminium and complex profile geometries. The consistent coordination of blade geometry, tooth shape, and manufacturing quality ensures high cutting performance that makes the difference between rework and parts ready for direct assembly for many companies.

Maximum stability and precision for high-quality aluminium cuts

The foundation for excellent cutting – stability and precision

A precise cut is not a coincidence, but the result of stable and reliable processes. The EVO SAW A600 is based on a solid, patented machine base with a total weight of 5.2 tons. This sturdy construction ensures that the saw operates with minimal vibrations and consistently delivers precise cut edges, even under extreme demands in series production. Thanks to the circular saw blade with a tolerance of less than 0.1 mm, almost flawless cutting patterns are achieved. This guarantees that the EVO SAW A600 maintains almost zero tolerance in the cut edges, even under high load. Users of EVO SAW circular saw blades notice a clear difference: while conventional blades often need to be resharpened or replaced after a short period, the EVO SAW A600 remains consistently efficient and ensures a long service life.

Optimal results for large daily volumes and demanding profile geometries

Ideal for thin-walled profiles and various aluminium cross-sections

The EVO SAW A600 provides stable cutting guidance, ensuring a clean cut edge and minimal burr formation. When processing thin-walled aluminium profiles, aluminium solid profiles, aluminium solid material profiles, and high daily volumes, the stability becomes a decisive advantage. With the EVO SAW A600, aluminium solid bars, aluminium flat bars, aluminium square bars, and aluminium round bars can be cut as efficiently as aluminium profiles with complex geometries. The precise geometry of the circular saw blade ensures that the results remain consistent over many cycles.

High tool life for cost-effective series production

Reduction of tool changes and downtime

For companies processing thousands of aluminium profiles and solid material every day, tools offering high tool life are crucial. The EVO SAW A600 is designed for a longer service life, meaning fewer tool changes and consequently less production downtime. This circular saw blade offers four times the tool life compared to conventional solutions, significantly improving the economic advantage. Less downtime means higher output, and consistently high cutting quality improves production performance significantly. The EVO SAW A600 is the ideal partner for companies that cut aluminium profiles, aluminium solid profiles, and aluminium solid bars in large quantities.

Luxembourgish tooth technology for extreme robustness and longevity

Long-lasting performance under high demands

Another outstanding feature of the EVO SAW A600 is the specially developed saw teeth, manufactured in Luxembourg. These are among the most resilient teeth used in industrial aluminium cutting. They are so robust that their tool life in professional applications is up to four times longer than that of conventional circular saw blades. For the user, this means fewer tool changes, less downtime, and consistently high cutting quality over a longer period of time.

Why negatively set teeth are so important for aluminium profiles

For precise cuts and less rework

The 120 negatively set teeth of the EVO SAW A600 ensure controlled engagement into the material, especially for aluminium profiles and sensitive surfaces. This negative tooth setting reduces the tool's tendency to grab and ensures a smooth cutting action that keeps the cut edges clean and the surface smooth. This is particularly important for thin-walled profiles or visible surfaces. The result is a cutting pattern that often requires significantly less rework. At the same time, process reliability is increased because the tool runs more smoothly and works consistently even at high daily output.

For companies with high production demands

The EVO SAW A600 was specifically developed for aluminium processing companies that perform between 30,000 and 50,000 cuts per day. In this production range, downtime, tool changes, and dimensional deviations are not only annoying but costly. The EVO SAW A600 effectively addresses these challenges. In window production, door production, façade construction, and industrial series manufacturing, companies immediately recognize the advantage: fewer interruptions, more parts per shift, and higher quality per profile.

Technical core data at a glance

Circular saw blade specification

Saw blade diameter: Ø 600 mm

Number of teeth: 120 teeth

Tooth geometry: negatively set, optimized for aluminium

Application: aluminium, aluminium profiles, aluminium solid profiles, solid material, series cutting

Operational advantage: Less downtime, fewer tool changes, higher output

Conclusion

The EVOMATEC circular saw blade EVO SAW A600 for aluminium and aluminium profiles with Ø 600 mm stands for industrial precision, high stability, and exceptionally long tool life. The combination of the massive machine base and precise tooth technology ensures consistently clean cuts, minimal burr formation, and reliable cutting quality, even in demanding series production. This solution is tailored for companies that cut large quantities of aluminium profiles, aluminium solid profiles, aluminium solid material profiles, aluminium solid bars, and aluminium flat bars daily, relying on consistently high dimensional accuracy. The EVO SAW A600 is a tool that improves productivity and quality in the long term and increases cost-effectiveness. EVOMATEC – Machines for precise aluminium profile machining.

Contact our team for a free consultation: Click here

English

English

German

German

French

French

Spanish

Spanish

Portuguese

Portuguese

Italian

Italian

Polish

Polish

Turkish

Turkish

Romanian

Romanian

Greek

Greek

Bulgarian

Bulgarian

Russian

Russian

Arabic

Arabic

Hindi

Hindi