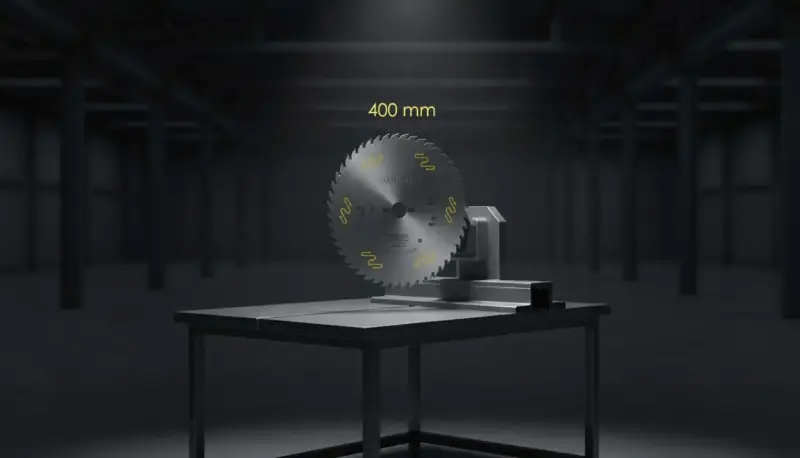

ALUMINIUM CIRCULAR SAW BLADE 400 MM EVO SAW A400

Circular Saw Blade for Aluminium Profiles with Ø 400 mm and 120 Negatively Set Teeth EVO SAW A400

Industrial Precision for Aluminium and Aluminium Profiles with Reference-Level Cutting Quality

In professional aluminium manufacturing, success is determined not only by the machine, but above all by the tool. A modern circular saw blade for aluminium must run stably at high volumes, deliver consistently low-burr cutting results and repeat exactly what was set once over many hours. This is precisely why the EVOMATEC EVO SAW A400 was developed for the reality of series production.

The circular saw blade for aluminium profiles EVO SAW A400 operates with a diameter of Ø 400 mm and 120 teeth that are deliberately negatively set. The result is a controlled, smooth cut specifically designed for aluminium and demanding profile geometries. Thanks to the consistent coordination of blade geometry, tooth design and manufacturing quality, it delivers cutting performance that, for many companies, makes the difference between rework and parts ready for direct assembly.

Patented machine base with 5.2 tons of weight for stability you can feel immediately

A precise cut is not created by coincidence, but by stability. The EVO SAW A400 is based on a patented machine construction with a total weight of 5.2 tons. This massive design forms the foundation for exceptionally high manufacturing quality and ensures maximum smooth running as well as consistently precise cutting results.

Imagine cutting with a circular saw blade with a tolerance below 0.1 mm and achieving a cutting quality that practically enables almost zero deviation. This is exactly what EVO SAW stands for.

Anyone who has worked with EVO SAW circular saw blades once and experienced that other blades often need to be resharpened multiple times or even replaced after a short time, while EVO SAW continues to cut reliably, cleanly and dimensionally accurately, will choose this quality permanently.

Especially with thin-walled profiles, high daily volumes and changing profile cross-sections, this stability becomes a decisive advantage: the cut runs smoothly, the cut edge remains clean, and the results stay consistent over many cycles. This creates process stability that is not only measurable, but also immediately noticeable in daily operation.

Highest manufacturing quality for permanently precise results

The EVO SAW A400 is manufactured according to the strictest quality standards. EVOMATEC deliberately relies on consistently precise production and the tightest manufacturing tolerances so that the system operates reliably in series production over the long term. The goal is a tool that delivers consistently clean results in continuous operation without the cutting quality declining throughout the day.

Tolerance below 0.1 mm for series production where dimensional accuracy is critical

When thousands of aluminium profiles are processed every day, one thing matters most: consistent dimensional accuracy. With the EVO SAW A400, EVOMATEC achieves a cutting tolerance below 0.1 mm. In practice, this often feels to many users as if the machine cuts “almost without tolerance” because the results remain exceptionally stable over long production runs.

This precision delivers several advantages: mitres fit more accurately, assemblies can be mounted faster, scrap decreases, and quality control becomes significantly more relaxed. Especially with system profiles where multiple components must align perfectly, a precision circular saw blade for aluminium is a direct lever for better processes and lower costs.

Luxembourg tooth technology: extremely robust, extremely durable

Another key factor of the EVO SAW A400 is what many underestimate: the teeth. The saw teeth are manufactured in Luxembourg and rank among the most durable solutions used in industrial aluminium cutting. For the user, this means one thing above all: significantly longer tool life compared to many common circular saw blades on the international market.

Under professional conditions, the tool life of this tooth quality can be up to four times longer than conventional solutions. This is a real economic advantage because fewer tool changes are required, less downtime occurs, and cutting quality stays consistent for longer. Many companies describe this effect very simply: once you buy this saw blade, in practice you gain a benefit that feels like having four circular saw blades for the price of one.

Why negatively set teeth are so important for aluminium profiles

The 120 negatively set teeth are not chosen by coincidence. Especially in aluminium, a negative tooth angle ensures controlled tooth engagement into the material. This reduces the tendency to grab, stabilises the cut and supports a clean surface finish, particularly on thin-walled profiles or sensitive, visible surfaces.

The result is a cutting finish that in many cases requires significantly less rework. At the same time, process reliability improves because the tool runs more smoothly and remains consistent even at high daily outputs.

Designed for aluminium machining companies with 30,000 to 50,000 cuts per day

The EVO SAW A400 is not a solution for occasional cuts. It was developed specifically for professional aluminium machining companies that process extremely high volumes every day, typically between 30,000 and 50,000 profiles per day. Exactly in this range, downtime, tool changes and dimensional deviations are not only annoying, but expensive.

EVOMATEC therefore focuses on what matters in high throughput: stability, precision, tool life and a cutting result that remains reliably reproducible. Anyone working in window manufacturing, door production, façade construction or industrial series production will recognise the benefit immediately: fewer interruptions, more parts per shift and better quality per profile.

Key technical data at a glance

Circular saw blade specification

- Blade diameter: Ø 400 mm

- Number of teeth: 120 teeth

- Tooth geometry: negatively set, optimised for aluminium

- Application: aluminium, aluminium profiles, series cutting

Your advantage in practice: less downtime, fewer tool changes, higher output

In high-performance cutting operations, the best tool is the one that works in the background. It should cut without discussion. This is exactly what the EVO SAW A400 is designed for: maximum process stability through extreme rigidity, repeatable results with extremely low deviation and tool life that noticeably stabilises material flow.

For high-throughput companies, this means a direct improvement in economic efficiency. Lower tool costs per cut, fewer production interruptions, less rework and a quality level that has a positive effect across the entire operation.

Conclusion

The EVOMATEC circular saw blade EVO SAW A400 for aluminium and aluminium profiles with Ø 400 mm and 120 negatively set teeth stands for industrial precision, maximum stability and exceptionally long tool life. The combination of a patented machine base and precise tooth technology ensures permanently clean, low-burr cutting performance even in demanding series production.

This solution is designed for companies that cut tens of thousands of profiles every day and depend on consistently high dimensional accuracy, reproducible cutting quality and reliable process stability.

EVOMATEC– Machines for precise aluminium profile machining.

English

English

German

German

French

French

Spanish

Spanish

Portuguese

Portuguese

Italian

Italian

Polish

Polish

Turkish

Turkish

Romanian

Romanian

Greek

Greek

Bulgarian

Bulgarian

Russian

Russian

Arabic

Arabic

Hindi

Hindi