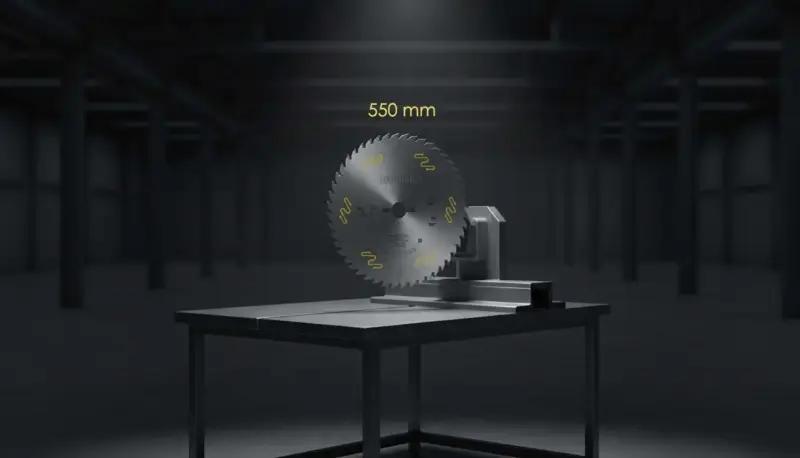

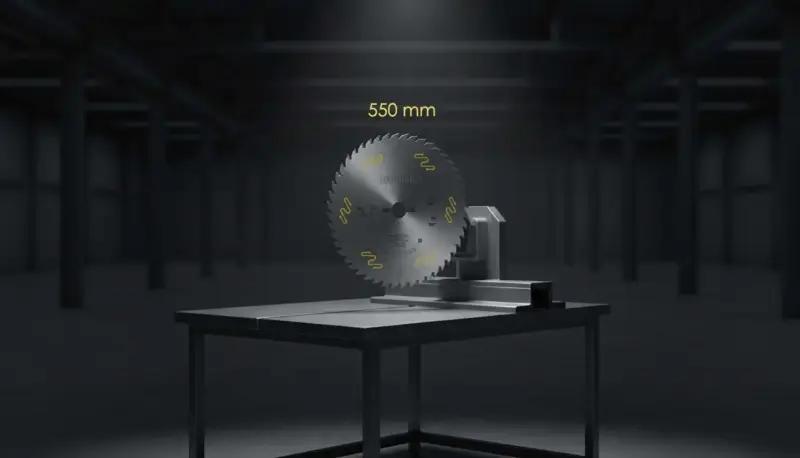

CIRCULAR SAW BLADE WITH 550 MM EVO SAW A550

Circular Saw Blade for Aluminium Profiles with Ø 550 mm and 120 Negatively Set Teeth EVO SAW A550

Industrial quality for aluminium, aluminium profiles and solid material with consistently precise cutting performance

In professional aluminium processing, quality is not created only at final assembly, but directly at the cutting stage. Especially at high quantities, the circular saw blade becomes the decisive factor: it determines whether profiles are separated cleanly, remain low-burr, and whether dimensional accuracy can be reliably reproduced over entire shifts. The EVOMATEC EVO SAW A550 was developed precisely for this reality in continuous industrial operation.

The circular saw blade for aluminium profiles EVO SAW A550 operates with a diameter of Ø 550 mm and 120 teeth that are consistently negatively set. This geometry ensures smooth engagement into the material, reduces vibrations and enables a controlled cutting pattern even on demanding cross-sections. The result is precise cutting edges on aluminium profiles, as well as on solid-material applications, for example aluminium solid profile, massive aluminium profile and aluminium solid material profile.

Process reliability in series cutting

Developed for consistent dimensional accuracy at high daily output

In industrial cutting, it is not single values that matter, but stability over hundreds or thousands of cuts. As soon as profiles are processed daily in large quantities, costs do not arise from sawing itself, but from deviations, rework and unnecessary downtime. This is exactly where the EVO SAW A550 comes in: it was designed for reproducible cutting quality that remains consistent even at high throughput.

Whether in the production of window, door and façade systems or in general profile machining: the saw blade supports a clearly stable process. This keeps cut edges clean, fits stable and makes assembly noticeably more efficient.

Ø 550 mm as an advantage for profiles and solid material

More cutting reserve and controlled cutting forces for demanding aluminium profiles

A circular saw blade with Ø 550 mm offers a practical benefit in aluminium production that becomes immediately visible in daily operation. The larger diameter enables stable cutting guidance, improves engagement reserve and supports controlled material removal, especially with thick walls and massive cross-sections. This pays off when both delicate profiles and robust solid material must be processed reliably.

The EVO SAW A550 is suitable, among other things, for:

Aluminium profiles in series cutting

Aluminium solid profile and massive aluminium profile

Aluminium solid material profile with high material density

Aluminium solid bar for precise cut-off cuts

Aluminium flat bar for clean, straight cut surfaces

Aluminium square bar for angle-accurate, stable results

Aluminium round bar for uniform cut edges without distortion

Hollow-chamber profiles, system profiles, window profiles, door profiles, façade profiles

Frame profiles, sash profiles, mullion profiles, transom profiles, coupling profiles

U-profiles, T-profiles, L-profiles, Z-profiles, H-profiles, C-profiles

Rectangular tubes, square tubes, round tubes, extrusion profiles, special profiles

This gives the saw blade an enormous range, from classic profile geometries to complex, project-specific profile cross-sections.

120 negatively set teeth for smooth cutting patterns

Low-burr cutting, less grabbing, high surface quality

The negative tooth setting is not just a technical feature in aluminium, but a decisive contribution to process reliability. While aggressive tooth geometries can tend to pull in, chatter or cause visible edge defects on aluminium, the negative design of the EVO SAW A550 ensures controlled, smooth engagement.

In practice, this means:

stable running even with changing profile cross-sections

reduced tendency to grab on thin-walled aluminium profiles

clean cut edges for visible surface areas

lower burr formation and less rework

reproducible quality in continuous operation

Especially with massive aluminium profiles, aluminium solid bars or heavy system profiles, this stability becomes a real advantage because the cut remains uniform and the cut surface looks professional.

Precision as an economic factor

When fits are right, assembly runs faster and scrap decreases

High dimensional accuracy is not a luxury in series production, but the foundation for stable production costs. The more consistent the cut, the lower the effort required for inspection, correction and rework. The EVO SAW A550 is designed to keep cutting quality stable over the long term so that profiles and solid material parts can be processed directly.

Typical advantages in operation:

mitres fit more precisely and faster

assemblies can be mounted more efficiently

material flow becomes calmer and more predictable

tool costs per cut decrease thanks to longer service life

less downtime due to reduced tool changes

This makes a circular saw blade not just a cutting tool, but a direct adjustment lever for more output.

Manufacturing concept for demanding production conditions

Robustly designed for high loads, long tool life and industrial repeat accuracy

The EVO SAW A550 is manufactured according to consistent quality standards to function reliably in industrial cutting over the long term. The decisive factor is not a single feature, but the coordination of blade body, tooth geometry and manufacturing precision. The goal is clear: a circular saw blade that cuts stably over long series and keeps cutting quality consistent throughout the day.

Many operations recognise this benefit especially in direct comparison: where conventional circular saw blades lose performance more quickly or have to be changed more often, the cutting performance of the EVO SAW A550 remains stable for longer. This reduces interruptions and stabilises the overall performance of the cutting line.

Developed for aluminium processors with high throughput

Ideal for window production, door production, façade construction and industrial profile manufacturing

The EVO SAW A550 is designed for companies that process aluminium daily on an industrial scale. Typical application areas include:

window and door production with high cutting quantities

façade construction and system profiles in series

cutting extrusion profiles and special profiles

separating solid material such as flat bar, square bar and round bar

production lines with clear cycle times and high output

Especially when large quantities of aluminium profiles and aluminium solid material profiles are processed daily, a stable circular saw blade determines profitability, quality and process reliability.

Key technical data at a glance

Circular saw blade specification EVO SAW A550

Saw blade diameter: Ø 550 mm

Number of teeth: 120 teeth

Tooth geometry: negatively set, optimised for aluminium

Application: aluminium, aluminium profiles, aluminium solid profile, solid material

Focus: low-burr cutting pattern, high dimensional accuracy, stable tool life

Conclusion

The EVOMATEC circular saw blade EVO SAW A550 for aluminium, aluminium profiles and solid material with Ø 550 mm and 120 negatively set teeth stands for process-reliable cutting results in industrial production. The controlled tooth geometry, stable cutting characteristics and continuous-operation quality ensure clean edges, reduced rework and a tool life that becomes economically noticeable in daily production.

EVOMATEC – Machines and tools for precise aluminium profile machining.

English

English

German

German

French

French

Spanish

Spanish

Portuguese

Portuguese

Italian

Italian

Polish

Polish

Turkish

Turkish

Romanian

Romanian

Greek

Greek

Bulgarian

Bulgarian

Russian

Russian

Arabic

Arabic

Hindi

Hindi