AUTOMATIC SAW WITH TAPPED HOLE UNIT EVO DDG

EVO DDG Automatic Saw with Thread Drilling Ø 500 mm for Aluminium Profiles

Servo-controlled profile feed, batch cutting, and integrated thread drilling for precise series production in aluminium profile processing

The EVO DDG is a high-performance automatic saw with thread drilling for efficient series processing of aluminium profiles. The machine design combines automated cutting as a profile automatic saw with an integrated thread drilling unit, so cutting and thread production take place in one continuous process. This makes the EVO DDG ideal for production in window, door, and facade construction, where aluminium profiles must be cut to defined lengths and then prepared directly for assembly.

Ø 500 mm saw blade for wide aluminium profiles and precise cutting quality

For separating wide profile cross-sections, the machine operates with a Ø 500 mm saw blade. The cutting speed adjustment enables profile-dependent parameter settings to support clean cut surfaces and a stable process. For series cutting, the EVO DDG offers a cutting accuracy of 0.2 mm, a minimum cutting length of 5 mm, and a defined remaining piece length of 270 mm for reliable process planning. This achieves reproducible results, even with changing profile geometries.

Automatic profile feed, batch cutting, and automatic clamping technology

The servo-controlled automatic profile feed ensures reliable material flow for batch cutting. The automatic clamping system fixes the aluminium profile securely in the machining zone, reduces profile movement, and supports consistently high cutting quality. The integrated conveyor is designed for daily production and offers a load capacity of 500 kg. The standard conveyor length is 4 m, allowing the machine to be easily integrated into line concepts, buffer sections, and cycle-accurate workflows.

Digital travel paths, touchscreen operation, and program memory

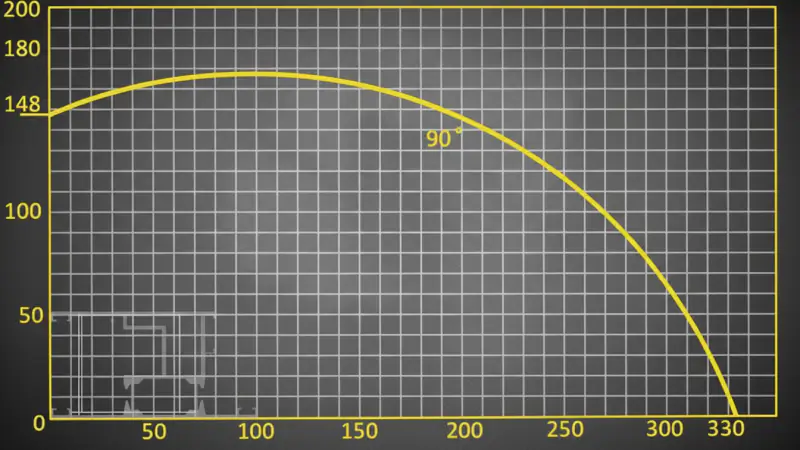

The EVO DDG provides digital adjustment of the saw blade travel path. The digital adjustment of the saw blade stroke travel is based on the profile geometry and supports repeat-accurate workflows with varying profile heights and cutting lengths. Operation is via a touchscreen control panel. With process programming and a large program memory, recurring machining programs can be called up quickly and processed in a standardized manner. In addition, a manual cutting speed setting is available for fine adjustments.

Thread drilling up to M10 for assembly-ready aluminium profiles

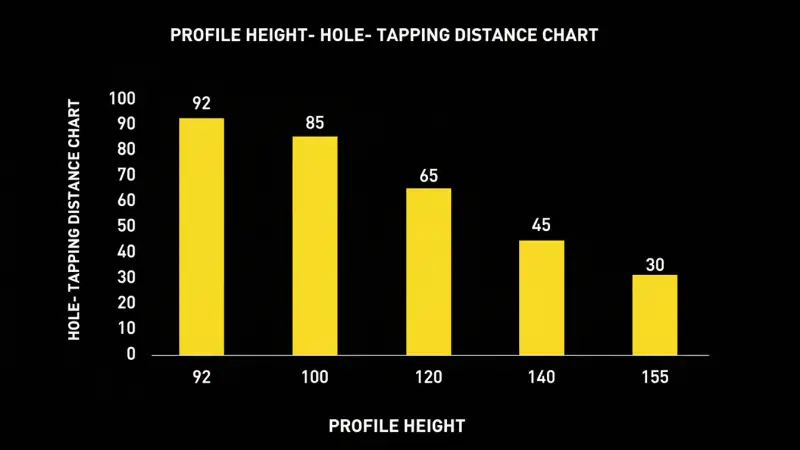

A key advantage of the EVO DDG is the integrated thread drilling for aluminium profiles. The ER16 tool holder is designed for process-reliable tool clamping. With a thread capacity up to M10 (max.), the machine covers typical thread applications as required in hardware assembly, connection elements, or system profiles. The positioning of the thread drilling can be reproducibly matched to the respective profile geometry using a diagram for profile height and hole/thread distance position. This makes machining predictable, repeat-accurate, and especially suitable for series production.

Safety and process stability in series production

For safe operation, the machine is equipped with a protective cover including a safety sensor. The standard equipment also includes a cooling system that stabilizes machining in aluminium profiles and supports consistent conditions at the cutting zone.

Technical Data EVO DDG

| Motor Power | 5.5 HP / 4 kW |

| Motor Speed | 3000 r.p.m |

| Frequency | 50 / 60 Hz |

| Current (400 V) | 8 A |

| Auxiliary Drive (230 V) | 0.8 kW, 3000 r.p.m, 4.83 A |

| Auxiliary Drive (220 V) | 0.8 kW, 3000 r.p.m, 4.83 A |

| Tool Holder | ER 16 |

| Thread Capacity | M10 (max.) |

| Saw Blade Diameter | Ø 500 mm |

| Saw Blade Bore | Ø 30–32 mm |

| Saw Blade Thickness | 4 mm |

| Saw Blade Speed | 2347 r.p.m |

| Air Pressure | 6–8 bar |

| Air Consumption | 40 L/min |

| Dimensions (L x W x H) | 6630 x 1340 x 1440 mm |

| Weight | 735 kg |

EVOMATEC – Machines for precise aluminium profile processing.

Request technical consultation: Click here

English

English

German

German

French

French

Spanish

Spanish

Portuguese

Portuguese

Italian

Italian

Polish

Polish

Turkish

Turkish

Romanian

Romanian

Greek

Greek

Bulgarian

Bulgarian

Russian

Russian

Arabic

Arabic

Hindi

Hindi