AUTOMATIC ALUMINIUM PROFILE SAW FOR ALUMINIUM PROFILES EVOM II 600

AUTOMATIC ALUMINIUM PROFILE SAW FOR ALUMINIUM PROFILES – EVOM II 600

Industrial Precision, Performance, and Efficiency in Aluminium Profile Cutting

Exceptional Cutting Quality in Aluminium Profile Processing

The EVOM II 600 automatic aluminium profile saw is a high-performance mitre saw engineered for precise, clean, and burr-free cutting of aluminium and light alloy profiles.

Equipped with a Ø 600 mm carbide-tipped saw blade, a hydro-pneumatic feed system, and a solid cast-steel construction, it provides maximum stability, repeatable precision, and long-term durability — ideal for window, door, façade, and structural profile manufacturing.

The EVOM II 600 combines advanced cutting technology, energy efficiency, and industrial-grade robustness in a single unit.

It is the premier choice for manufacturers demanding superior precision, reliability, and efficiency in aluminium profile processing.

Hydro-Pneumatic Technology – Precision and Control in Every Cut

The hydro-pneumatic feed system ensures smooth, controlled cutting motion and automatically adjusts cutting speed based on profile geometry, wall thickness, and material.

This technology minimizes vibration, extends saw blade life, and reduces material waste to an absolute minimum.

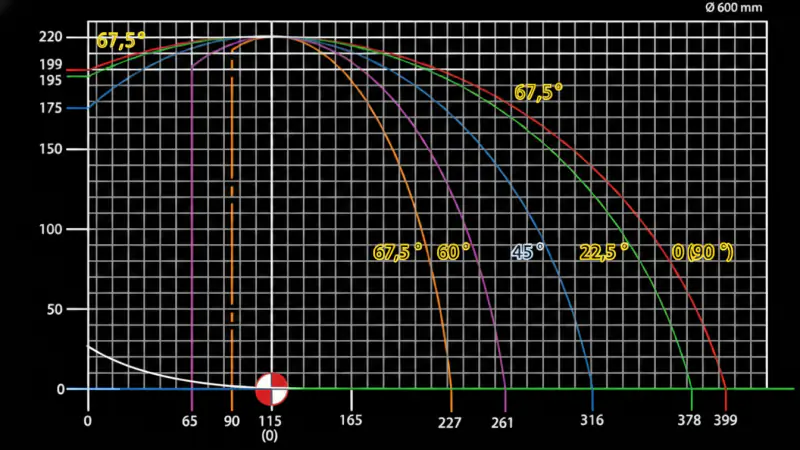

The wide cutting range from −67.5° to +67.5°, with preset stops at 0°, 15°, 22.5°, 30°, 45°, and 67.5°, offers maximum flexibility for mitre cuts, frame assemblies, and special profile sections.

With its automatic speed regulation and intelligent motion control, the EVOM II 600 delivers perfectly consistent, repeatable results — even for complex aluminium profiles in demanding production environments.

Industrial Safety and User Comfort at the Highest Standard

The EVOM II 600 complies fully with all current CE safety regulations.

A protective safety cover with integrated sensor control prevents operation when open, ensuring maximum operator safety throughout the cutting process.

Pneumatic vertical and horizontal clamps securely fix the workpiece during cutting, eliminating movement or vibration.

The combination of automatic angle adjustment, hydro-pneumatic feed, and regulated cutting speed ensures consistently high-quality results, even during multi-shift operation.

Robust Industrial Design and Energy-Efficient Performance

The heavy-duty cast-steel frame of the EVOM II 600 guarantees vibration-free operation and long-term dimensional accuracy, even under continuous load.

A high-performance 4 kW (≈ 5.5 HP) motor drives the Ø 600 mm carbide-tipped saw blade, delivering exceptional power and cutting capacity for thick-walled aluminium profiles and non-ferrous materials.

The integrated cooling system prevents overheating, protects the workpiece, and ensures smooth, burr-free cutting surfaces.

Operating at 6–8 bar air pressure with a consumption of only 58 L/min, the EVOM II 600 achieves energy-efficient, quiet, and low-maintenance performance — perfect for 24/7 industrial use.

Technical Specifications

Performance Data

Saw Blade Diameter: Ø 600 mm (carbide-tipped)

Spindle Speed: 2,193 rpm

Motor Power: 4 kW (≈ 5.5 HP)

Voltage / Frequency: 400 V / 50 Hz

Cutting and Feed System

Cutting Angle Range: −67.5° to +67.5°, with fixed stops at 0°, 15°, 22.5°, 30°, 45°, 67.5°

Feed System: hydro-pneumatic, automatically regulated

Clamping System: pneumatic — vertical and horizontal cylinders

Cooling System: integrated

Air and Dimensions

Air Pressure: 6–8 bar

Air Consumption: 58 L/min

Machine Dimensions: 3,920 × 1,230 × 1,675 mm

Weight: 331 kg

Advantages of the EVOM II 600 Automatic Aluminium Profile Saw

Precision and Control

Hydro-pneumatic feed for smooth, controlled cutting motion

Wide cutting range of ±67.5° for maximum flexibility

Integrated blade cooling for burr-free, high-quality cutting edges

Stability and Safety

Pneumatic clamping system for vibration-free workpiece fixation

CE-certified safety cover with integrated sensor monitoring

Heavy cast-steel frame for long-lasting precision and rigidity

Efficiency and Reliability

Energy-efficient operation with low air consumption

Maintenance-friendly design with durable industrial components

Ideal for serial production with maximum repeat accuracy

Typical Applications

The EVOM II 600 is universally applicable in professional aluminium processing and widely used in industrial manufacturing environments, including:

Window and Door Production: precision cutting of aluminium frame and sash profiles

Façade and Glass Frame Construction: accurate cuts for mullion, transom, and cladding systems

Structural and System Profile Fabrication: aluminium frameworks and modular structures

Serial Production: aluminium components for industrial and architectural applications

Precision Cutting: for machine building, metal construction, and lightweight fabrication

Whether in workshop operations or fully automated production lines, the EVOM II 600 consistently delivers precise, repeatable results at the highest level of productivity.

Conclusion

The EVOM II 600 automatic aluminium profile saw stands for industrial precision, maximum efficiency, and long-term reliability.

With its 4 kW high-performance drive, hydro-pneumatic feed system, and pneumatic clamping technology, it ensures clean, burr-free, and dimensionally accurate cuts for every application.

It is the ultimate solution for manufacturers in the window, door, and façade industries seeking technological innovation, energy efficiency, and superior cutting quality.

EVOMATEC – Machinery for Precision Aluminium Profile Processing

Request Technical Consultation

Click here to contact our technical specialists for detailed consultation and project support.

English

English

German

German

French

French

Spanish

Spanish

Portuguese

Portuguese

Italian

Italian

Polish

Polish

Turkish

Turkish

Romanian

Romanian

Greek

Greek

Bulgarian

Bulgarian

Russian

Russian

Arabic

Arabic

Hindi

Hindi