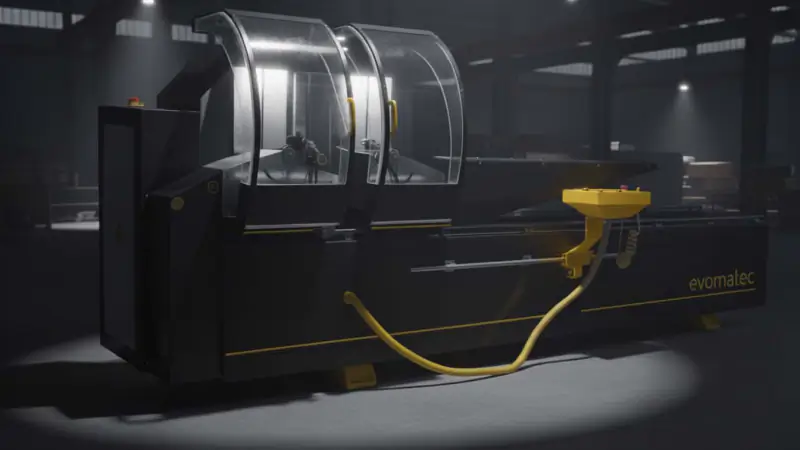

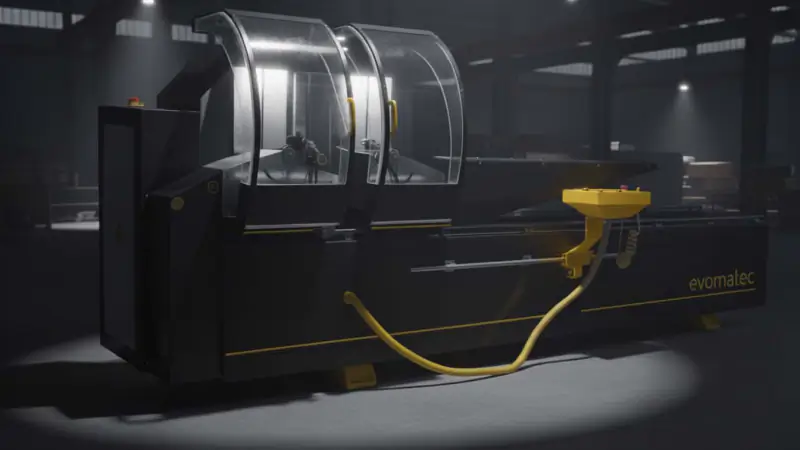

AUTOMATIC ALUMINIUM PROFILE DOUBLE MITRE SAW EVOG CUT AI ECO

Automatic Aluminium Profile Double Mitre Saw EVOG CUT AI ECO

Highly efficient cutting of aluminium profiles for windows, doors, and façade construction

The EVOG CUT AI ECO is an industrial double mitre saw for precise, fast, and repeatable cutting of aluminium profiles in serial production. As a robust double mitre saw for aluminium profiles, it has been developed for companies that require consistent cut quality, short cycle times, and process-reliable workflows when cutting aluminium profiles. Thanks to double-sided processing, the double mitre saw aluminium profiles is ideally suited for frame and sash production, where two profile corners are cut within a defined sequence.

Double mitre saw for aluminium profiles with automatic positioning and variable angles

Automatic length stop for reproducible profile cutting

The moving unit automatically travels to the programmed dimension and supports structured cutting of aluminium profiles with high repeatability. This allows serial orders to be processed efficiently, while dimensional accuracy remains consistent when cutting aluminium profiles.

Mitre cuts from 45° to 90° for internal angles

The saw units enable mitre cuts in an angle range from 45° to 90° and are designed for internal angles. In practice, the EVOG CUT AI ECO is often used as a double mitre saw for aluminium profiles 45 degrees and as a double mitre saw for aluminium profiles 90 degrees when changing geometries in profile cutting must be covered reliably.

Process stability as the key to economical aluminium profile machining

Consistent cycle times and reproducible quality in serial production

For industrial machining of aluminium profiles, the decisive factors alongside maximum cutting precision are long-term stable process control. In serial production, it is not only the individual cut that matters, but the sum of repeatability, cycle-time consistency, operator safety, and reproducible workflows that determines profitability. This is exactly where the EVOG CUT AI ECO positions itself as a professional double mitre saw: it combines a robust machine design built for continuous operation with clearly structured operating logic, supporting predictable production with consistent quality when cutting aluminium profiles.

Standardized workflows to reduce scrap and rework

As an industrial double mitre saw aluminium profiles, the EVOG CUT AI ECO is designed to reduce typical fluctuations in daily production and to standardize processes. This means defined workflows, reliable positioning, clean cut results, and reproducible cut quality across multi-shift operation. Especially with changing profile cross-sections and frequent job changes, it is crucial that the double mitre saw for aluminium profiles can be set up quickly, operated easily, and run stably during production. This reduces scrap, rework, and downtime, while increasing throughput and delivery capability.

Economy and purchasing criteria for double mitre saws

Price-performance focus when selecting a double mitre saw

In procurement, the decision is often driven not only by technology, but also by an overall economic assessment. Many companies specifically look for a solution that convinces as a price-performance product for double mitre saws, because it not only enables clean cuts on aluminium profiles, but also keeps process costs stable in the long term. When comparing different systems and evaluating the price for double mitre saws, users typically consider the combination of performance scope, operating convenience, process reliability, and operating costs.

Productivity lowers unit costs when cutting aluminium profiles

Especially when cutting aluminium profiles, every minute of machine time directly impacts the cost per component. A process-stable double mitre saw supports consistent utilization, clear calculations, and improved production planning. That is why many projects deliberately search for a high price-performance ratio double mitre saw, because it helps align productivity and quality without compromising profitability.

Price focus in purchasing and practical requirements in production

In day-to-day operations, purchasing and production often set different priorities. While production focuses on process stability and repeatability when cutting aluminium profiles, purchasing often emphasizes comparisons aimed at the best price for double mitre saws. The key is that the machine is not only attractive in the quotation, but also delivers sustainable performance in real operation. In this context, the most advantageous price is often considered when technical equipment and expected output are evaluated in relation to the investment.

Lowest price and total cost assessment in real operation

Many companies deliberately do not decide purely on the absolute lowest price. Nevertheless, procurement requests and internal comparisons regularly include the requirement for double mitre saws with lowest price, especially when multiple machine classes are being evaluated. The EVOG CUT AI ECO is often assessed as an economical option because it combines solid industrial design with a clear, practice-oriented operating concept, ensuring reliable use in everyday production.

Conclusion for industrial use

Convincing in the long term through stable processes and transparent profitability

In the end, the overall balance is what counts: consistent cut quality on aluminium profiles, safe workflows, stable cycle times, and an investment that pays off in production. That is why the EVOG CUT AI ECO is considered in many applications as a solution where not only the double mitre saw price convinces, but also the long-term use. For this reason, users and decision-makers often refer to a best price-performance ratio for double mitre saws when performance, equipment, and operating costs work together efficiently in practice.

Technical Data EVOG CUT AI ECO

| Feature | Value |

|---|---|

| Voltage / Frequency | 380 V / 50 Hz |

| Total Power | 2 × 1.5 kW |

| Air Pressure | 6–8 bar |

| Air Consumption | 50 l/min |

| Saw Blade Diameter | Ø 450 |

| Max. Profile Height | 120 mm |

| Max. Profile Width | 120 mm |

| Machine Length | 3900 mm |

| Machine Width | 1080 mm |

| Machine Height | 1350 mm |

| Machine Weight | 620 kg |

| Table Length | 1500 mm |

| Max. Cutting Length | 3320 mm |

| Min. Cutting Length | 500 mm |

EVOMATEC – Machines for precise aluminium profile machining

Contact:info@evomatec.de

English

English

German

German

French

French

Spanish

Spanish

Portuguese

Portuguese

Italian

Italian

Polish

Polish

Turkish

Turkish

Romanian

Romanian

Greek

Greek

Bulgarian

Bulgarian

Russian

Russian

Arabic

Arabic

Hindi

Hindi