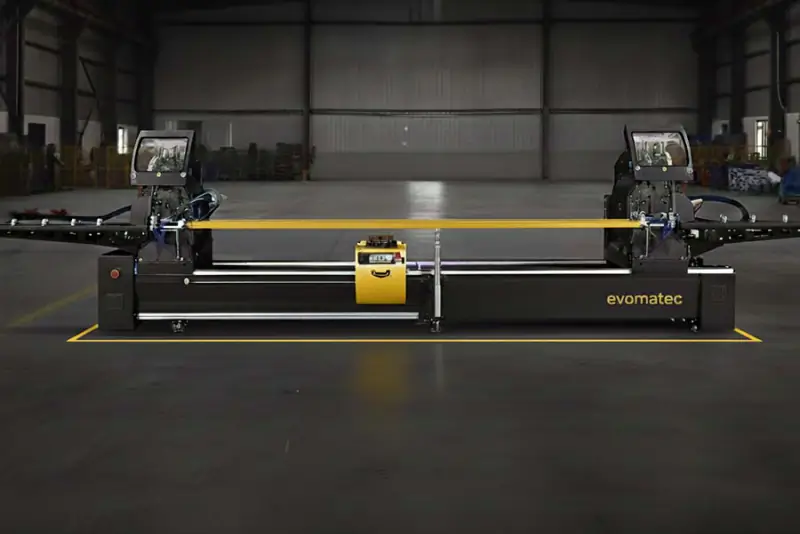

DOUBLE MITRE SAW FOR PVC WINDOW PROFILES EVOG VR

Double Mitre Saw for PVC Window Profiles EVOG VR – Servo Precision for Industrial Series Production

EVOG VR: Double Mitre Saw for PVC window profiles with servo technology, automatic angle adjustment, and hydro-pneumatic feed – precise, fast, and CE-certified.

Why the EVOG VR Sets New Standards in Window Manufacturing

The Double Mitre Saw for uPVC Window Profiles EVOG VR from Evomatec combines servo-controlled 3-axis angle adjustment with hydro-pneumatic feed and a stable machine base.

The result: clean, burr-free mitres, maximum repeatability, and outstanding productivity—ideal for window, door, and PVC profile processing in high-volume industrial production.

Key Benefits at a Glance

Perfect mitres for frame and sash profiles without rework

Automatic head positioning for fast profile changeovers

Consistent cutting without material overheating thanks to spray cooling

CE-certified safety and ergonomic operation via touchscreen interface

Application Profile: Precision and Efficiency in PVC Cutting

In modern PVC window production, the quality of mitre cuts determines fit, sealing, and visual finish.

The EVOG VR delivers consistent results even with complex multi-chamber profiles and high production volumes.

Servo-driven angle adjustment allows quick transitions between –22.5° to +45°, while the hydro-pneumatic feed system ensures smooth, controlled cutting motion.

Technical Features of the EVOG VR

| Feature | Specification |

|---|---|

| Saw Blades | Ø 550 mm, carbide-tipped (HM) |

| Motor Power | 2 × 3 kW / 4 HP |

| Cutting Length | 480 – 5050 mm |

| Angle Range | Servo-controlled –22.5° to +45° |

| Feed System | Hydro-pneumatic control |

| Positioning Speed | Up to 40 m/min |

| Air Pressure / Consumption | 6–8 bar / approx. 70 L/min |

| Total Power | Approx. 9.1 kW |

| Voltage / Frequency | 400 V / 50–60 Hz |

| Machine Weight | Approx. 1490 kg |

Standard Equipment

Servo-controlled 3-axis angle adjustment

Pneumatic clamping cylinders (horizontal and vertical)

Spray cooling system for PVC profiles

Movable head with roller conveyor

Digital feed control, 10″ touchscreen display

Enclosed safety hood, emergency stop, and CE compliance

Optional Features

EVOSOFT cutting optimization software with data interface

Barcode printer, Ethernet/USB connectivity

Automatic chip extraction system

Support extensions for long profiles

Process Reliability: Consistent Burr-Free Cutting Quality

The combination of servo-driven technology and hydro-pneumatic feed eliminates vibration and material melting.

The integrated spray cooling system keeps the blade and profile at optimal temperature levels.

The result: smooth cutting surfaces that can be welded or corner-cleaned immediately—without rework.

Advantages for Your Production

1. Maximum Dimensional Accuracy

Servo-controlled head positioning and digital angle regulation achieve tenth-millimeter precision, ideal for PVC window and door frames.

2. Rapid Setup Times

Automatic angle selection and pre-programmed profile settings minimize downtime and increase throughput—especially in series production.

3. Durability and Cost Efficiency

A robust steel frame, protected linear guides, and low-maintenance design guarantee long service life and low operating costs.

4. Ergonomics and Safety

Intuitive touchscreen operation, clear process visualization, and CE-certified safety systems ensure efficient and secure operation.

Typical Areas of Application

Window Manufacturing: Precision mitre cutting for frame and sash profiles

Door Production: Accurate 45° and 90° cuts for plastic frame components

Façade Construction: Dimensionally accurate cutting for PVC and hybrid profiles

General Profile Processing: Suitable for PVC, ABS, polycarbonate, PMMA, and similar materials

Quality “Made for Precision”

Each EVOG VR Double Mitre Saw is fully tested—mechanically, electrically, and software-wise—before delivery.

All machines are CE-certified, fully documented, and ready for integration into production lines via barcode, EVOSOFT, or Ethernet/USB connectivity.

This ensures process reliability, traceability, and future-proof system integration.

Conclusion – EVOG VR: The Cost-Efficient Solution for Perfect Mitres

The EVOG VR Double Mitre Saw for PVC Window Profiles combines servo precision, automatic angle adjustment, hydro-pneumatic feed, and CE-certified safety.

For companies seeking clean cuts, high throughput, and long-term reliability, the EVOG VR is the ultimate choice for modern industrial window and door production.

Contact our team for a free consultation: Click here

English

English

German

German

French

French

Spanish

Spanish

Portuguese

Portuguese

Italian

Italian

Polish

Polish

Turkish

Turkish

Romanian

Romanian

Greek

Greek

Bulgarian

Bulgarian

Russian

Russian

Arabic

Arabic

Hindi

Hindi