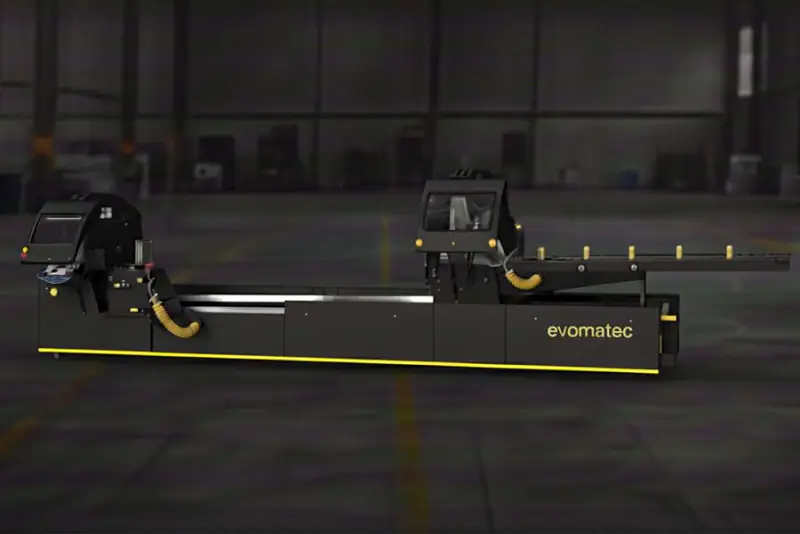

DOUBLE MITRE SAW FOR PLASTIC EVOG VSA

Double Mitre Saw for Plastic EVOG VSA – High-Precision Industrial Technology for PVC and Plastic Profiles

Advanced Double Mitre Saw Technology for Plastic Profile Cutting

Industrial Precision for PVC and Plastic Profiles

The Double Mitre Saw for Plastic EVOG VSA from Evomatec represents the latest generation of industrial precision cutting technology for PVC and plastic profiles.

It combines servo-controlled head adjustment, hydro-pneumatic feed, and digital angle control in one system—uniting productivity, precision, and efficiency for the modern manufacturing environment.

With its robust machine frame, accurate cutting motion, and intelligent control system, the EVOG VSA sets new benchmarks for window, door, and façade profile production in industrial and workshop applications alike.

Precision Cutting for PVC and Plastic Profiles

In industrial window and door production, the accuracy of mitre cutsectly determines the tightness, durability, and dimensional precision of the finished frame.

The EVOG VSA Double Mitre Saw was developed to meet these demands—offering servo-controlled angular positioning, consistent feed motion, and clean, burr-free surfaces.

Automatic head movement between –22.5°, –45°, 90°, and +45°, with manual fine adjustment for intermediate angles, provides both flexibility and precision for serial and custom manufacturing.

Technical Features of the EVOG VSA

| Feature | Specification |

|---|---|

| Saw Blades | Ø 550 mm, carbide-tipped (HM) |

| Motor Power | 2 × 3 kW / 4 HP |

| Cutting Length | 480 – 5050 mm |

| Angle Adjustment | –22.5°, –45°, 90°, +45° (hydro-pneumatic) |

| Positioning Speed | 40 m/min |

| Air Requirement | 6–8 bar / 100 L/min |

| Total Power | 7.4 kW |

| Voltage | 400 V / 50–60 Hz |

| Weight | Approx. 1450 kg |

Standard Equipment

Servo-controlled head positioning system

Ø 550 mm carbide-tipped saw blades

Digital display for head position and angle values

Pneumatic clamping (horizontal and vertical)

Hydro-pneumatic feed system

Adjustable spray-cooling unit

Movable head conveyor system

Complete CE-certified safety equipment

Optional Equipment

Barcode and production tracking system

Ethernet/USB interfaces

Cutting optimization software

Chip and dust extraction unit

Powerful Industrial Performance

The EVOG VSA Double Mitre Saw for Plastic combines high cutting speed with vibration-free operation and energy-efficient servo drives.

By allowing both heads to cut simultaneously, production time is reduced by up to 40%, while maintaining maximum accuracy and surface quality.

The hydro-pneumatic feed control ensures smooth, steady cutting motion, prevents material melting, and produces flat, dimensionally stable surfaces.

Advantages of the Double Mitre Saw EVOG VSA

1. Servo Precision for Reproducible Results

Automatic head control with digital angle positioning delivers sub-millimeter cutting accuracy, even for complex profile shapes.

2. Large Cutting Capacity

With a maximum cutting length of 5050 mm, the EVOG VSA is ideal for large plastic frames and long PVC profiles.

3. Industrial Quality with Minimal Maintenance

The heavy-duty cast steel frame and high-precision linear components ensure long-term durability and low maintenance requirements.

4. Energy Efficiency and CE Safety

Equipped with modern servo drives and hydraulic systems, the machine achieves low energy consumption with maximum performance, fully compliant with CE standards.

5. User-Friendly Operation

A clear touchscreen interface, automatic head movement, and intuitive software make operation fast, efficient, and user-oriented.

Typical Applications

Window Production: Precise cutting of frame and sash profiles

Door Manufacturing: 45° and 90° mitre cuts for door frames

Façade Construction: Accurate cuts for plastic and hybrid profiles

Industrial Profile Processing: Machining of PVC, ABS, acrylic glass, and polycarbonate

Thanks to its versatility, the EVOG VSA is equally suitable for automated production lines and manual workshop environments.

Step-by-Step Working Process

Insertion and Clamping: Place the plastic profile and fix it pneumatically.

Servo Positioning: Saw heads automatically move to the desired angle.

Hydro-Pneumatic Feed: Smooth cutting motion without deformation or vibration.

Spray Cooling: Prevents overheating and ensures clean, burr-free surfaces.

Return and Repeat: Automatic cycle restart for continuous production.

This workflow produces perfect mitres ready for assembly, without the need for any manual rework.

Quality, Safety, and CE Compliance

Every EVOG VSA Double Mitre Saw is manufactured in Europe under CE and ISO standards and undergoes rigorous quality testing.

Evomatec ensures maximum safety, energy efficiency, and long-term mechanical stability—from electronic control systems to mechanical precision components.

Future Readiness and Cost Efficiency

The EVOG VSA is fully Industry 4.0-compatible and can be integrated into digital manufacturing systems.

Through USB or Ethernet interfaces, production data can be tracked, analyzed, and optimized in real time.

The result: increased productivity, lower operating costs, and sustainable competitiveness.

Conclusion – Precision, Efficiency, and Stability in Plastic Profile Cutting

The Double Mitre Saw for Plastic EVOG VSA stands for technical excellence, energy efficiency, and industrial reliability in profile machining.

With servo-driven head adjustment, hydro-pneumatic feed, and robust machine construction, it delivers top-level performance for modern window, door, and façade manufacturing.

Contact our team for a free consultation: Click here

English

English

German

German

French

French

Spanish

Spanish

Portuguese

Portuguese

Italian

Italian

Polish

Polish

Turkish

Turkish

Romanian

Romanian

Greek

Greek

Bulgarian

Bulgarian

Russian

Russian

Arabic

Arabic

Hindi

Hindi