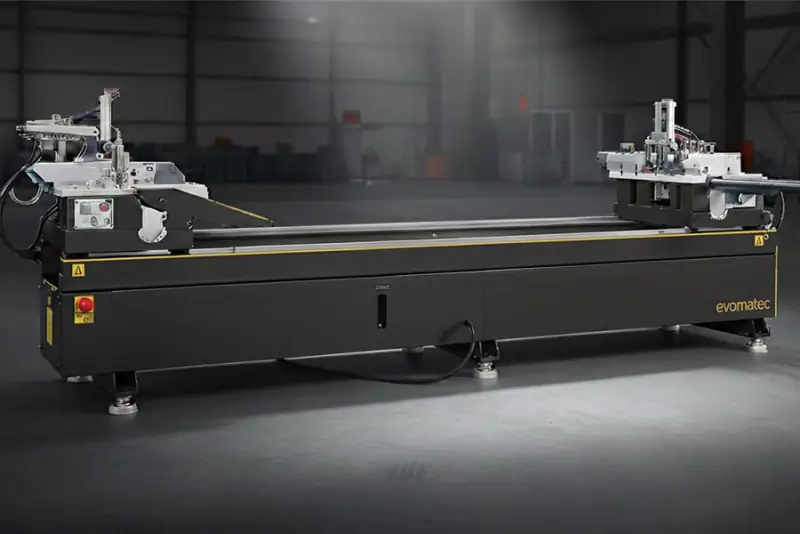

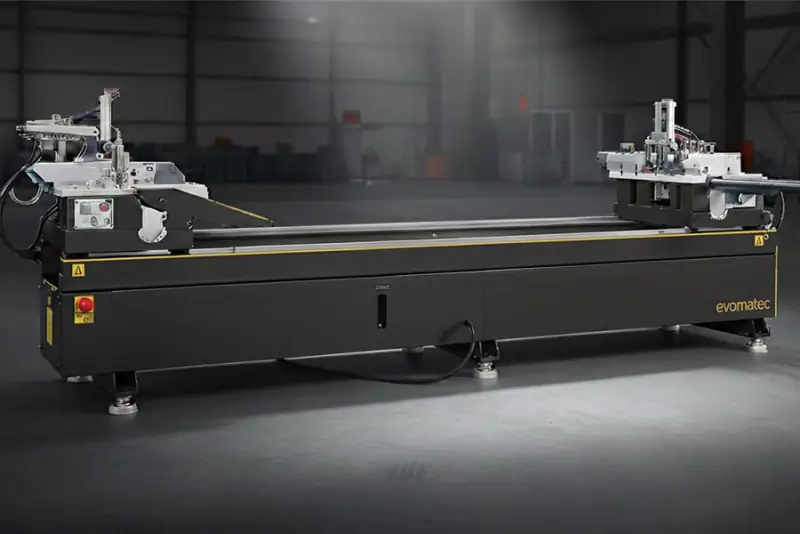

DOUBLE HEAD CORNER CRIMPING MACHINE FOR ALUMINIUM PROFILES EVOA II

Double-Head Corner Crimping Machine for Aluminium Profiles – EVOA II

Maximum Precision, Dual Performance, and Industrial Efficiency in Frame Assembly

Fully Automatic Corner Crimping with Two Synchronized Hydraulic Heads

The double-head corner crimping machine for aluminium profiles EVOA II is a hydraulically powered precision machine designed for simultaneous pressing of both frame corners.

With two synchronized hydraulic heads, it delivers double productivity without compromising on accuracy — ideal for industrial-scale window, door, and façade manufacturing.

Thanks to its two-stage hydraulic pressure system, automatic pressure control, and heavy-duty steel frame, the EVOA II achieves stress-free, form-stable, and long-lasting corner joints with minimal operator intervention and maximum repeatability.

Hydraulic Precision for the Highest Demands

The EVOA II combines the power of a dual-head hydraulic system with the flexibility of manual fine adjustment.

Both press heads work in perfect synchronization to crimp two corners of an aluminium frame at the same time — the perfect solution for manufacturers seeking productivity, precision, and efficiency.

Hydraulic Core Technology

Two-Stage Pressure System: Controlled pressure buildup for stress-free, exact joints

Automatic Pressure Regulation: Uniform pressing force on both frame sides

Hydraulic Pressure up to 150 bar: Ensures maximum strength and airtight corner connections

Reinforced Steel Frame: Guarantees vibration-free operation and long machine life

Manual Fine Adjustment: Enables quick adaptation to various profile cross-sections

Profile Compatibility: Suitable for wide, tall, and thermally broken aluminium profiles

Technical Specifications of the EVOA II Double-Head Corner Crimping Press Machine

Hydraulic Pressure: 150 bar

Air Pressure: 6–8 bar

Motor Power: 3–4 HP (2.2–3 kW)

Speed: 1,430 rpm

Profile Processing Length: 495–3,500 mm

Maximum Profile Height: 150 mm

Machine Dimensions (L × W × H): 4,425 × 1,605 × 1,410 mm

Machine Weight: 990 kg

System Type: Double-head hydraulic press

Safety Standard: CE-certified (EU Machineryective)

Advantages of the EVOA II 2 Head Corner Crimping Machine

Double Productivity

Simultaneous pressing of both corners reduces cycle times by up to 50%, enabling faster production without sacrificing quality.

High Dimensional Accuracy

Two synchronized hydraulic heads guarantee identical press force on both sides of the frame for consistent and precise results.

Vibration-Free Operation

The heavy-duty base construction minimizes vibration, ensuring stable and repeatable corner joints.

Energy Efficiency

Optimized hydraulic control reduces power consumption and operating costs while maintaining full performance.

Long Service Life

Durable components and high-quality sealing systems minimize maintenance needs and ensure reliable long-term operation.

CE-Certified Safety

Complies with all European machinery and occupational safety standards, ensuring operator protection in industrial use.

Quick Profile Changeover

Ideal for high-volume production with flexible adaptation to different aluminium profile types.

Application Areas

The EVOA II double-head corner crimping press is the perfect solution for companies seeking high production capacity and consistent quality.

Typical Applications:

Manufacturing aluminium windows and door frames

Producing façade profiles and curtain wall systems

Crimping thermally broken aluminium profiles

Assembly of special frames and large structural elements

Series production with automatic dual crimping cycle

Its dual-head design makes it suitable for both mass production and precision custom fabrication.

How It Works – Two Corners in One Cycle

The EVOA II operates through a precise, fully automated process:

1. Profile Positioning

Aluminium profiles are placed at both ends and automatically clamped in position.

2. Centering

The system aligns both frame sides perfectly using automatic centering.

3. Two-Stage Hydraulic Cycle

Initial positioning pressure secures the profiles, followed by full-force pressing for the final crimp.

4. Dual-Side Crimping

Both frame corners are pressed simultaneously and synchronously.

Result:

Perfect 90° corner joints

Stress-free and form-stable connections

No profile deformation

Dimensional accuracy even in mass production

Quality, Safety, and CE Compliance

Each EVOA II is built to meet the highest European quality standards.

Evomatec uses certified hydraulic systems, robust steel structures, and precision-engineered crimping tools to guarantee long-term production reliability.

Every machine undergoes complete mechanical, electrical, and hydraulic testing before delivery.

Evomatec ensures CE-compliant assembly, provides operator training, preventive maintenance, and a fast spare parts service to ensure maximum uptime.

Economic Efficiency and Investment Value

The EVOA II double-head corner crimping press machine increases productivity and reduces manufacturing costs through:

50% shorter cycle times

Lower labor requirements

Reduced rework and waste

Energy-efficient continuous operation

Low-maintenance hydraulic systems

This machine offers rapid ROI thanks to higher throughput, shorter lead times, and lower operational costs — a clear advantage for modern metal fabrication companies.

Conclusion – Dual Precision, Maximum Efficiency

The EVOA II double-head corner crimping press for aluminium profiles sets the standard for precision, speed, and stability in aluminium frame assembly.

With its synchronous dual-head system, advanced hydraulic control, and robust industrial build, it’s the ideal choice for manufacturers seeking to combine quality and efficiency in one seamless process.

Whether for window, door, or façade production, the EVOA II ensures identical, repeatable, and long-lasting corner connections that meet the highest standards of modern aluminium construction.

Evomatec – Evolution. Machines. Technology.

Contact: info@evomatec.de

Request Free Consultation: Click Here

English

English

German

German

French

French

Spanish

Spanish

Portuguese

Portuguese

Italian

Italian

Polish

Polish

Turkish

Turkish

Romanian

Romanian

Greek

Greek

Bulgarian

Bulgarian

Russian

Russian

Arabic

Arabic

Hindi

Hindi