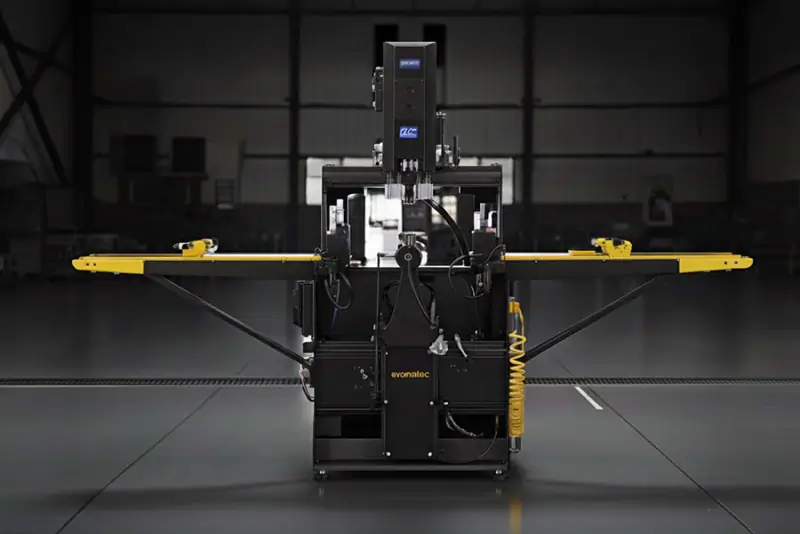

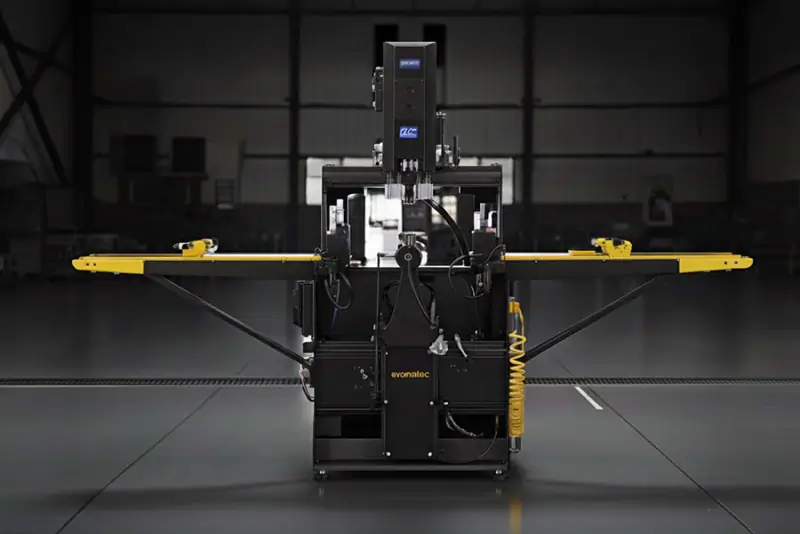

COPY ROUTER FOR PLASTIC PROFILES WITH 3 SPINDLES EVOG IV

Copy Router for Plastic Profiles with 3 Spindles EVOG IV – Maximum Precision with Minimal Cycle Time

High Performance for PVC and Plastic Profiles

Industrial Efficiency and Precision Engineering

The EVOG IV copy router for plastic profiles with 3 motors from Evomatec is designed for maximum productivity in industrial profile processing.

Three independently controlled high-speed spindles perform handle cut-outs, lock openings, hinge slots, and multi-point grooves simultaneously – all within a single machining cycle.

The result: shorter cycle times, consistent dimensional accuracy, and superior surface finish for PVC and plastic profiles used in windows, doors, and façades.

Three Motors – One Step Ahead in Performance

The EVOG IV employs a simultaneous multi-surface milling concept: the front, top, and rear surfaces of the profile are machined in parallel.

Each axis can be individually configured for milling depth, feed rate, and tool geometry.

A precise linear guiding system, pneumatic clamping technology, and an active tool cooling system ensure smooth operation, extended tool life, and consistently high part quality – even when machining thin-walled PVC profiles.

Key Advantages at a Glance

Triple milling in one operation for maximum productivity

Individually adjustable parameters per motor for complex geometries

Low-vibration linear guides for dimensional accuracy and clean edges

Integrated cooling system for stable tool temperatures

CE-certified safety and ergonomic operation for reliable production

Technical Core Data of the EVOG IV

Drive System: 3 × high-speed spindles, each individually adjustable

Spindle Speed Range: up to 12,000 rpm

Standard Tool Holder: Ø 8 mm milling cutter, optional 5–10 mm

Pneumatic Clamping System: included as standard for secure profile fixing

Compressed Air Requirement: 6–8 bar, optimized consumption for efficient operation

Machine Design: torsion-resistant frame, precision linear guides, industrial-grade electronics

Reliable Applications in Window and Door Production

Window Manufacturing: milling of handle openings, lock slots, multi-point locking and hinge grooves, drainage slots

Door Production: machining of hardware recesses, multi-lock cut-outs, hinge and strike plate openings

Façade Construction: milling of connection and installation grooves in plastic and composite profiles

Series Production: fast changeovers via copy templates and parameterized programs

Quality That Pays Off

The combination of simultaneous machining, short setup times, and minimal material waste significantly reduces unit costs.

The EVOG IV delivers burr-free surfaces, tight tolerances, and repeatable profile quality – ensuring perfectly aligned, visually flawless components for assembly.

Control and Ergonomics

A clearly structured control panel with intuitive parameter input simplifies setup and batch processing.

Quick-clamping modules shorten profile changeovers, while built-in diagnostic and monitoring functions increase process stability and operator safety.

Miter Saw for Plastic Profiles – The Perfect Line Integration

In modern production lines, efficiency peaks when miter cutting and multi-surface milling work seamlessly together.

Prepared profile lengths and frames are first cut to precise angles on a miter saw for plastic profiles, and the EVOG IV then performs the functional machining – such as handle, lock, and drainage slot milling.

This synchronized workflow minimizes material handling and maximizes dimensional precision throughout the production line.

Future-Proof Profile Machining

Thanks to modular tooling concepts, energy-efficient pneumatics, and optional data interfaces, the EVOG IV can be integrated into modern, networked production environments.

It is a scalable solution for manufacturers facing growing batch sizes, variant diversity, and stricter dimensional tolerance demands.

Conclusion – Premium Performance for Advanced Serial Production

The EVOG IV copy router for plastic profiles with 3 motors combines productivity, precision, and process reliability.

Simultaneous milling on three surfaces drastically reduces cycle times, stabilizes quality, and lowers costs – making it the ideal choice for manufacturers in window, door, and façade production who seek industrial-grade quality with economic efficiency.

Contact our team for a free consultation:Click here

English

English

German

German

French

French

Spanish

Spanish

Portuguese

Portuguese

Italian

Italian

Polish

Polish

Turkish

Turkish

Romanian

Romanian

Greek

Greek

Bulgarian

Bulgarian

Russian

Russian

Arabic

Arabic

Hindi

Hindi