ALUMINIUM PROFILE MACHINING CENTER EVO A LILIPUT

Profile Machining Center for Aluminium Profiles EVO A LILIPUT

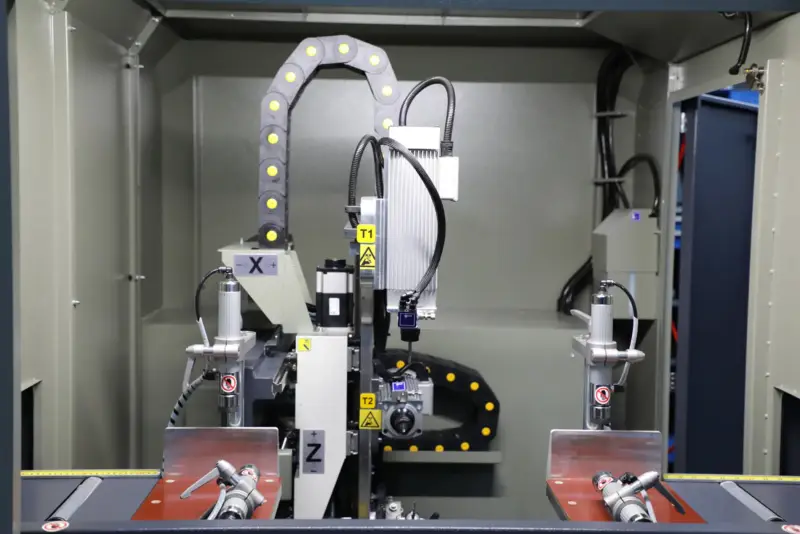

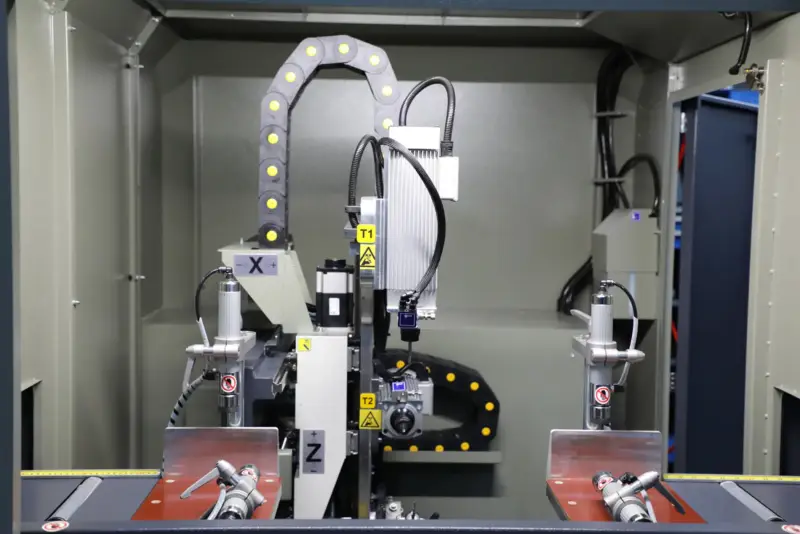

Compact 3-Axis NC Machining Center with Copy Router Function for Precise Machining of Aluminium Profiles on Three Profile Sides

The EVO A LILIPUT is a modern, particularly compact profile machining center for professional machining of aluminium profiles in industrial production. As a powerful CNC profile machining center, this system combines the most important work steps for window manufacturing, door manufacturing and façade construction in a stable, reproducible process. Anyone looking for a reliable machining center that performs typical hardware and functional machining operations in aluminium profiles cleanly, quickly and with repeat accuracy will find the EVO A LILIPUT a practice-oriented CNC machining center with a clear focus on productive series workflows and efficient single-part production.

In modern profile production, it is not only the machining quality that matters, but above all process reliability: short setup times, clear positioning, stable clamping technology and an operating concept that minimizes sources of error. This is exactly where the EVO A LILIPUT, as an aluminium machining center, comes in. Thanks to machining on three profile surfaces, this aluminium profile machining center is ideally suited for typical tasks in hardware machining. These include, among others, lock case milling, handle drilling, hinge pockets, elongated hole machining, slot milling as well as defined recesses and contours. This makes the EVO A LILIPUT not only a machining center for aluminium profiles, but a profile machining center for aluminium profiles consistently designed for real production requirements.

Machining Center: Aluminium Profiles for Window Manufacturing, Door Manufacturing and Façade Construction

In window and door manufacturing, precise, clean machining of profiles is crucial so that hardware, locks and handles fit without play and later complaints are avoided. As a CNC machining center for aluminium profiles, the EVO A LILIPUT supports the fast implementation of recurring machining steps and ensures that both series production and flexible job production remain efficient. Especially in areas such as façade construction or with large, heavy profiles, stable clamping technology and reproducible axis movements are essential. The EVO A LILIPUT was developed exactly for this purpose: as CNC machines for aluminium with a compact machine concept, high repeat accuracy and a clearly structured workflow.

Whether milling aluminium profiles, aluminium profilesdrilling or clean slot milling of aluminium profiles, in practice what counts is that each machining step runs in a controllable, fast and repeatable way. That is why this CNC milling center for aluminium profiles works with a user-friendly operating concept and parametric program templates that simplify recurring machining operations and increase process reliability. This makes CNC aluminium profile machining predictable: less adjustment effort, less searching time, fewer errors, better quality.

CNC Milling Center: Aluminium Profiles with Copy Router Function and Parametric Program Templates

A key advantage of the EVO A LILIPUT is the integrated copy router function. In many workshops, this is exactly the key to implementing frequently recurring machining operations on aluminium profiles quickly and cleanly. As a CNC milling center for aluminium profiles, the system is therefore ideal when contours and recesses need to be produced reliably based on a pattern or template, without the operator having to write complex programs. This makes aluminium profile CNC machining efficient even for teams that value clear processes and simple operation.

With the parametric program templates, typical machining operations such as lock case recesses, handle hole patterns or defined hinge pockets can be selected and adjusted quickly. In daily production this means: CNC profile machining for aluminium is standardized, yet remains flexible enough to cover special cases and different profile systems. Anyone looking for a machine for aluminium profiles that delivers not only high precision but also real productivity gains benefits from exactly this combination of NC logic, copy routing and simple parameters.

Hardware Machining of Aluminium Profiles with Clear Process Logic

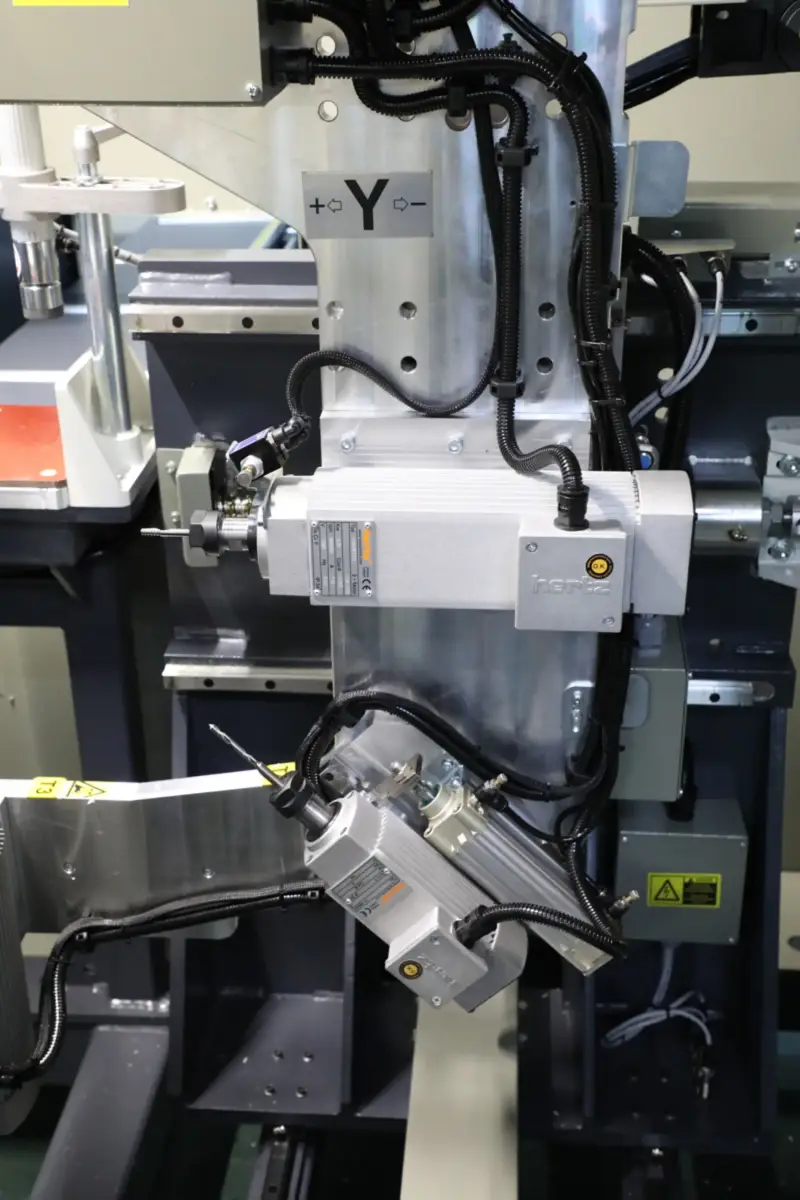

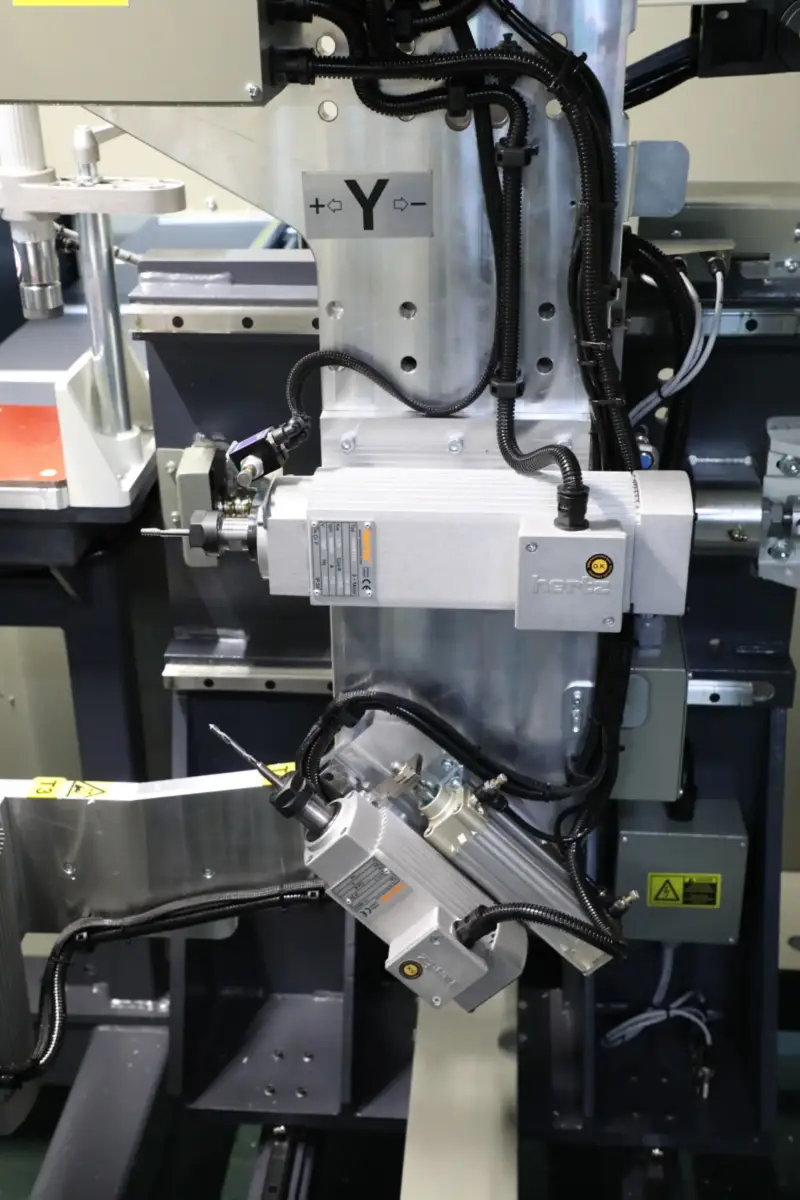

Hardware machining is a bottleneck in many operations because many individual steps come together: measuring, marking, clamping, milling, drilling, reworking. The EVO A LILIPUT reduces this complexity by enabling machining on three profile sides and allowing the spindles to operate independently. This combines typical work steps such as aluminium lock case machining, handle drilling for aluminium profiles and milling hinge pockets for profiles into a structured workflow.

Especially milling elongated holes for aluminium profiles requires clean edges and uniform dimensions so that hardware and fastenings fit precisely. Likewise, when slot milling for aluminium profiles, it is important that the milling path is guided stably and that the clamping technology holds the profile securely. The EVO A LILIPUT supports these requirements with pneumatic clamping technology and a clear machine geometry that enables machining of aluminium profiles with reproducible quality.

Positioning, Clamping and Repeat Accuracy as the Basis for CNC Profile Machining

In practice, positioning is often the difference between fast production and time-consuming rework. That is why the EVO A LILIPUT provides clear operator support: right and left profile stops as well as laser marking help to align profiles quickly and safely. This keeps CNC profile machining stable, even when different profile cross-sections and jobs are machined in alternation.

The combination of horizontal and vertical pneumatic clamping collets ensures that the profile is held reliably during milling aluminium profiles and drilling aluminium profiles. This is particularly important for longer profiles or for machining close to the profile edge. This is exactly where the benefit of a professional profile machining center becomes clear: less vibration, better surfaces, clean edges and precise hole patterns.

Productive Speed with Short Cycle Time

In addition to accuracy, speed matters. The EVO A LILIPUT achieves positioning speeds of up to 30 m/min on X, Y and Z. In combination with clear program templates and fast alignment, CNC aluminium profile machining becomes significantly more economical. This benefits not only series manufacturers, but also workshops that produce many different parts and still need short lead times.

With three spindles and a maximum speed of 18,000 rpm, the system becomes a reliable CNC machining center for aluminium profiles that enables common machining operations with high cutting quality. The ER 20 tool holder ensures stable tool clamping in daily use. The maximum tool diameter of 13 mm reliably covers typical applications in profile machining.

Technical Data EVO A LILIPUT

| Specification | Value | Unit / Note |

|---|---|---|

| Travel X Axis (longitudinal) | 350 | mm |

| Travel Y Axis (lateral) | 150 | mm |

| Travel Z Axis (vertical) | 120 | mm |

| Positioning Speed X Axis | 30 | m/min |

| Positioning Speed Y Axis | 30 | m/min |

| Positioning Speed Z Axis | 30 | m/min |

| Compressed Air Pressure | 6 to 8 | bar |

| Compressed Air Consumption | 40 | L/min |

| Max. Electrical Connected Load | 12 | kW |

| Voltage | 400 V 3P PE AC | |

| Frequency | 50 to 60 | Hz |

| Spindles, Quantity | 3 | with fan cooling |

| Max. Spindle Power | 3 | kW |

| Max. Spindle Speed | 18.000 | rpm |

| Tool Holder | ER 20 | |

| Maximum Tool Diameter | 13 | mm |

| Clamping Range Profile Support Xmax / Xmin | up to 660 / min open | mm |

| Clamping Range Profile Support Ymax / Ymin | up to 150 / min open | mm |

| Clamping Range Profile Support Zmax / Zmin | up to 120 / min open | mm |

| Control, Display | 10 | inch touchscreen |

| Data Transfer | USB | standard |

| Smart CAM Postprocessing | optional | |

| Clamping Collets, Standard Quantity | 4 | pcs |

| Machine Dimensions (L x W x H) | 2.900 x 2.370 x 2.045 | mm |

| Net Weight | 800 | kg |

| Gross Weight | 1.000 | kg |

Standard Equipment and Options

Standard Equipment for Safe Machining of Aluminium Profiles

For a CNC machining center to be ready for series production, the basic equipment must cover daily requirements. The EVO A LILIPUT is therefore supplied with a cooling system, laser marking and profile stops. The pneumatic clamping collets in horizontal and vertical design ensure that CNCprofile machining for aluminium remains stable and repeatable. In addition, 3 pieces of 6 mm milling cutters are included as a basis for many standard machining operations.

Optional Accessories for More Flexibility

Anyone who wants to use the machine as CNC machines for aluminium across a wide range of parts can expand the equipment with additional cutter sizes and the optional Servo Control Profile Support to support long profiles even more conveniently. This turns the EVO A LILIPUT into a flexible machine for aluminium profiles for changing requirements in window manufacturing, door manufacturing and façade construction.

EVOMATEC – Your Partner for the Future of Aluminium Profile Machining

Contact: Click Here

English

English

German

German

French

French

Spanish

Spanish

Portuguese

Portuguese

Italian

Italian

Polish

Polish

Turkish

Turkish

Romanian

Romanian

Greek

Greek

Bulgarian

Bulgarian

Russian

Russian

Arabic

Arabic

Hindi

Hindi