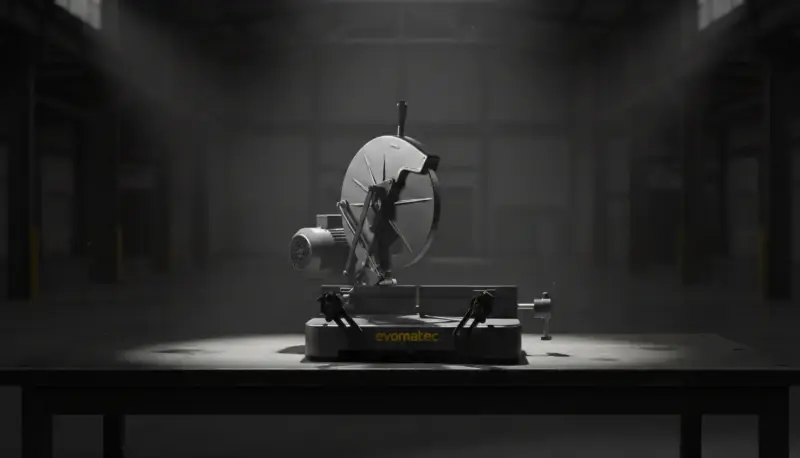

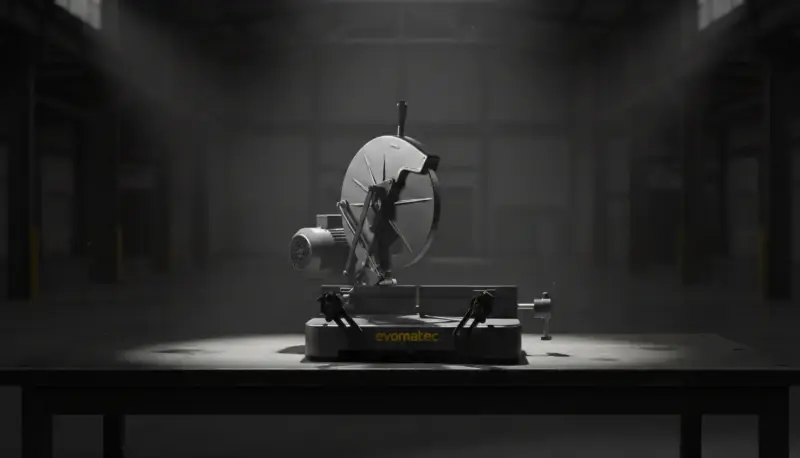

MITRE SAW EVO ECO II

Mitre Saw EVO ECO II, Professional Solution for Precise, Clean and High-Volume Cutting

Why Speed, Quality and Repeatability Are Critical in Aluminium Profile Cutting

Aluminium window and door systems, facade applications, railing systems, solar energy constructions and industrial profile solutions are a rapidly growing market today, because both aesthetics and durability are expected. In this market, competition is not won only by price, but also by standardization in production, dimensional accuracy and the quality of corner joints. The cutting station at the beginning of production determines the quality of the entire line. Because in aluminium profiles, the cutting angle and surface quality affect all subsequent processes such as drilling, milling, corner joining, pressing and assembly.

For this reason, choosing a mitre saw developed for aluminium profile cutting is a strategic investment that directly increases workshop performance. EVO ECO II, with a 400 mm circular saw blade diameter, ball and fork bearing system, adjustable clamping unit, and the ability to perform multi-angle cuts to the right and left, is specifically designed for businesses that aim for clean cuts, low burr formation and high repeatability in aluminium profiles.

What Is EVO ECO II and Which Businesses Is It Suitable For

EVO ECO II is a portable mitre saw solution that operates with a 400 mm circular saw blade. It was developed especially for workshops that target accuracy, continuity and occupational safety in light alloys and aluminium profile cutting. Although the machine can also be used on materials such as PVC and wood, its core strength is revealed in aluminium profile production and applications in aluminium window and door manufacturing.

This machine becomes an ideal option for the following businesses:

Workshops for aluminium window and door production

Facade and curtain wall installation companies

Manufacturers of aluminium railings, handrails and glass balcony systems

Producers of supporting structures for solar panels

Teams for industrial aluminium profile cutting and assembly

Project-based teams working on-site for installation and assembly

The portable design means not only mobility, but above all flexibility in workflow. Performing cuts quickly in production or directly at the installation site reduces material handling time and shortens delivery times.

Why a Specialized Mitre Saw Is Required for Aluminium Profile Cutting

Compared to PVC, aluminium is a harder material and brings the following risks during cutting:

Burr formation due to the wrong blade and unstable movement

Scratches and deformation on the cut surface

Angle deviation and gaps in corner joints

Vibration during cutting and reduced surface quality

Dimensional errors caused by profile slippage in the clamp

These risks reduce production quality and increase labor costs at the same time. Deburring, surface correction and re-cutting create significant time losses by the end of the day. EVO ECO II aims to reduce these risks through its ball bearing system and precision continuity via locking.

Key Advantages of EVO ECO II for Aluminium Profiles

When choosing a mitre saw, it is not enough to look only at motor power. In aluminium profiles, the real difference is created by machine stability, clamping structure and repeatable angle accuracy.

Cleaner and More Stable Cutting with a 400 mm Circular Saw Blade

The 400 mm blade diameter creates a more stable cutting line in aluminium profiles. This is an advantage especially for large cross-sections and aluminium systems with different geometries. With the correct selection of the circular saw blade, the cut surface becomes smoother and the amount of burr is reduced.

30–32 mm Blade Adapter Bushing for Blade Flexibility

Blade selection is a critical topic in workshops processing aluminium. Thanks to the adapter bushing, compatibility with different blade options is ensured, and the business becomes more flexible in blade sourcing.

Ball and Fork Bearing System to Reduce Vibration

In aluminium profiles, vibration directly deteriorates surface quality and reduces angle accuracy. The ball and fork bearing system stabilizes the cutting movement and supports cleaner cutting results. This strengthens quality standardization in businesses performing high-volume cutting.

Adjustable Clamping System for Strong Fixation

If aluminium profiles are not fixed correctly during cutting, they may slip. This is both a safety risk and a cause of dimensional errors. The adjustable clamping system provides safer clamping across different profile sizes. The optional second clamp increases stability especially for long profiles.

Right-Left Cutting Capability at Standard Angles

Although the most common angles in aluminium window and door systems are 45° and 90°, some systems may also require special angles such as 15°, 22.5° and 30°. EVO ECO II enables cutting to the right and left at the following angles:

0°, 15°, 22.5°, 30°, 45°, 90°

These angle options enable faster production planning across different systems.

Consistent High Cutting Accuracy with Locking

The angle locking mechanism is a critical advantage for repeatability. If dozens of profiles are cut at the same angle throughout the day for the same project, locking keeps the angle consistent on every piece. This reduces errors in corner joining operations.

Technical Specifications and Cutting Capacity

The table below lists the main technical specifications and maximum cutting capacities of EVO ECO II.

| Technical Specification | Value |

|---|---|

| Model name | EVO ECO II |

| Voltage | 230 / 380 V (optional) |

| Power | 1.5 kW / 2 Hp |

| Frequency | 50–60 Hz |

| Speed | 3,000 rpm |

| Blade diameter | 400 mm |

| Blade adapter bushing | 30–32 mm |

| Angles (right-left) | 0°, 15°, 22.5°, 30°, 45°, 90° |

| Max cutting capacity 90° (height x width) | 120 x 200 mm |

| Max cutting capacity 90° (height x width) | 135 x 150 mm |

| Max cutting capacity 45° (height x width) | 120 x 140 mm |

| Weight net / gross | 59 / 69 kg |

| Machine dimensions | 657 x 512 x 575 mm |

| Wooden crate dimensions (length x width x height) | 76 x 66 x 75 cm |

Note: Actual cutting performance on aluminium profiles may vary depending on the profile geometry and the type of blade used.

Standard and Optional Equipment

Standard Equipment

2 Allen keys

Optional Equipment

400 mm blade

Second clamp

In aluminium profile cutting, a second clamp significantly improves cutting accuracy, especially on long profiles. It reduces twisting and slippage of the profile, resulting in more stable and cleaner cuts.

EVO ECO II’s Contribution to Aluminium Window and Door Production

In aluminium window and door production, cutting quality directly affects assembly quality. If the cut is not accurate, corners do not close properly, gasket gaps occur, aesthetics deteriorate and sealing values decrease. This leads to customer dissatisfaction and increased warranty and rework costs.

By standardizing cutting, EVO ECO II supports the following advantages:

Less burr and cleaner cut surfaces

Better fit and tighter corner joints

Lower scrap rate

Faster assembly and less need for corrections

Reduced operator errors and shorter training time

These effects increase profitability, especially in large project-based jobs and in serial production lines.

On-Site Aluminium Cutting Advantage with a Portable Design

In the aluminium window and door sector, on-site cutting is often needed. Because dimension revisions, differences encountered during installation, or the need to prepare additional parts later can occur. A portable mitre saw increases the speed of installation teams and raises the likelihood of finishing the job on the same day.

Fast correction cuts on the construction site

Quick adaptation to last-minute dimension updates in the project

Reduced part handling and transport time

Working without returning to the workshop

Practical Evaluation for the Purchase Decision

For an aluminium workshop, beyond the price of a mitre saw, the total operating cost is also important. Choosing the wrong machine can eliminate the low-price advantage in a short time. Therefore, the following criteria should be evaluated together:

Profile types to be cut and maximum cross-section

Daily cutting quantity and production target

Need for angle variety

Expectations for burr and surface quality

Requirement for on-site use

Need for an optional second clamp

Blade selection and blade cost

Based on this evaluation, the most suitable configuration for your business can be determined and the right quotation can be prepared.

Frequently Asked Questions

Is EVO ECO II suitable for cutting aluminium profiles

Yes, it is suitable especially for applications that target precise, clean and repeatable cuts in aluminium profiles.

What is the most important factor when buying a mitre saw

For aluminium, the most important factor is stability and secure clamping. The correct blade selection also directly affects the cut surface.

When is a second clamp needed

A second clamp is recommended for long profiles, large cross-sections or jobs requiring high precision.

Does it work with 230 V

Yes, 230 / 380 V options are offered upon request. The connection must match your facility’s electrical infrastructure.

Reliable and Professional Cutting Standard in Aluminium Profile Production

EVO ECO II provides a strong portable solution for businesses that want to standardize cutting quality in aluminium and aluminium profiles. The 400 mm circular blade capacity, stable bearing system, adjustable clamping structure and precision continuity through locking create an ideal combination for professionals who target cleaner, faster and more repeatable cutting both in the workshop and on-site.

If you would like to request a quotation, please share the profile types to be cut, the maximum cross-section and your daily production target, so we can quickly recommend the most suitable machine configuration.

English

English

German

German

French

French

Spanish

Spanish

Portuguese

Portuguese

Italian

Italian

Polish

Polish

Turkish

Turkish

Romanian

Romanian

Greek

Greek

Bulgarian

Bulgarian

Russian

Russian

Arabic

Arabic

Hindi

Hindi