MITER SAW FOR PLASTIC PROFILES EVOM II 600

MITER SAW FOR PLASTIC PROFILES – EVOM II 600

Industrial precision, hydro-pneumatic feed technology, and robust performance for professional PVC processing

Precise cutting for PVC, uPVC, and plastic profiles

The EVOM II 600 PVC miter saw by Evomatec is specifically designed for precise cutting of PVC, uPVC, and plastic profiles.

This powerful industrial saw combines a 600 mm carbide-tipped blade, hydro-pneumatic feed technology, and a heavy-duty machine body to deliver exceptional precision, smooth operation, and long-term reliability.

With its solid construction, pneumatic clamping systems, and finely adjustable feed control, it is the perfect solution for companies in window, door, and façade production that demand clean, accurate, and burr-free cuts.

Hydro-pneumatic feed technology – control and consistency

The hydro-pneumatic feed system of the EVOM II 600 ensures a smooth, vibration-free cutting motion and precisely adjusts the feed speed to match the material.

This allows PVC and plastic profiles to be cut cleanly and evenly without thermal deformation.

This advanced system ensures consistently high cutting quality — even with delicate, multi-chamber, or coated profiles.

The constant feed motion reduces tool wear and minimizes material stress, extending the life of the saw blades and eliminating the need for post-processing.

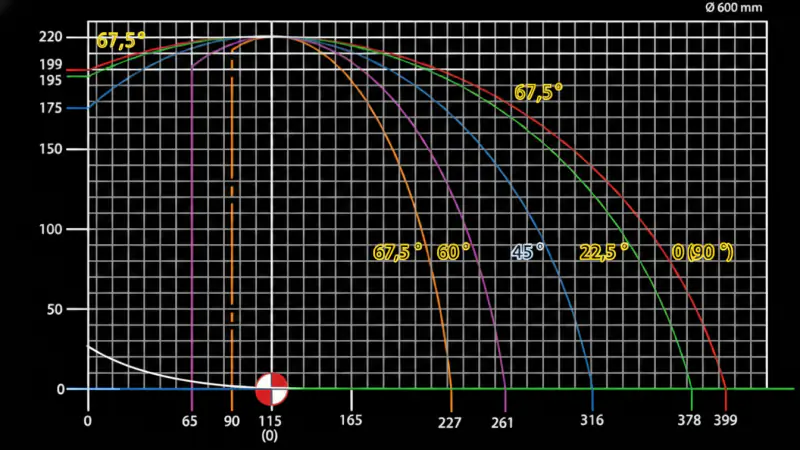

The manually adjustable miter range from –67.5° to +67.5°, with fixed stops at 0°, 15°, 22.5°, 30°, 45°, and 67.5°, enables precise adjustments for various frame and profile geometries.

Precision, safety, and ease of operation in industrial use

The EVOM II 600 combines industrial cutting power with outstanding safety and operator comfort.

Its enclosed safety hood with sensor control allows cutting operations only when the cover is fully closed — a crucial feature for CE-certified safety compliance.

Pneumatic vertical and horizontal clamps hold profiles securely in place, preventing movement during cutting.

Even long or flexible PVC profiles remain stable, ensuring precise and repeatable cutting results.

The ergonomic control panel allows easy adjustment of feed rate, cutting speed, and angles — making the machine ideal for both skilled professionals and high-volume production lines.

Industrial design – stability and energy efficiency

The EVOM II 600 is engineered for continuous operation in demanding industrial environments.

Its heavy-duty cast-steel frame guarantees vibration-free cuts and uniform power transmission, even with large PVC cross-sections.

A powerful 4 kW (≈ 5.5 HP) motor drives the 600 mm carbide-tipped blade at 2,193 rpm — ideal for precise cutting of PVC, uPVC, and composite profiles.

The integrated cooling system minimizes heat buildup during cutting, ensuring smooth, clean, and melt-free surfaces.

Operating at 6–8 bar air pressure and consuming only 58 L/min, the EVOM II 600 delivers energy-efficient, low-noise, and low-maintenance performance — even under heavy production loads.

Technical specifications of the EVOM II 600

| Feature | Specification |

|---|---|

| Saw blade diameter | Ø 600 mm (carbide-tipped, for PVC and plastic) |

| Rotation speed | 2,193 rpm |

| Motor power | 4 kW / 5.5 HP |

| Voltage / Frequency | 400 V / 50 Hz |

| Cutting angle range | –67.5° to +67.5°, fixed stops at 0°, 15°, 22.5°, 30°, 45°, 67.5° |

| Feed system | Hydro-pneumatic, manually adjustable |

| Clamping system | Pneumatic, vertical and horizontal |

| Cooling system | Integrated |

| Air pressure | 6–8 bar |

| Air consumption | 58 L/min |

| Machine dimensions (L × W × H) | 3,920 × 1,230 × 1,675 mm |

| Weight | 331 kg |

Typical applications in the construction industry

Window manufacturing

Precise miter cuts for PVC frames, sashes, and outer frame profiles — ideal for perfectly fitted corner joints.

Door manufacturing

Accurate cuts for PVC casings, thresholds, and system profiles with high dimensional precision.

Façade and conservatory construction

Clean cutting of large PVC elements, frames, and cladding systems.

Series production of PVC components

High repeat accuracy and consistent surface quality even at high production volumes.

Technical plastics processing

Efficient, dimensionally accurate cutting of profiles for machinery, interior construction, and plastic technology applications.

Advantages of the EVOM II 600 PVC miter saw

Precise and clean cutting quality

The hydro-pneumatic feed system provides smooth, vibration-free motion for burr-free cutting surfaces.Flexible miter range

The manually adjustable cutting angle from ±67.5° allows precise adaptation to any profile geometry.Robust machine construction

Heavy cast-steel frame ensures stability, quiet operation, and long service life under industrial workloads.Energy-efficient and low-maintenance

Low air consumption, optimized pneumatics, and durable components reduce operating costs.CE-certified safety

Sensor-controlled safety hood and emergency stop system provide maximum operator protection.Ergonomic operation

Intuitive control panel, simple angle adjustment, and secure clamping mechanisms increase productivity.

Evomatec – technology that builds trust

The EVOM II 600 embodies Evomatec’s philosophy: precision, quality, and industrial reliability.

Each machine is manufactured in accordance with European CE standards, electrically tested, and mechanically calibrated.

With a global service network of over 270 locations, Evomatec ensures dependable technical support, spare parts availability, and long-term customer satisfaction.

The EVOM II 600 represents German engineering excellence and sustainable performance in professional PVC profile machining.

Conclusion – precision and efficiency in industrial PVC cutting

The EVOM II 600 miter saw combines hydro-pneumatic cutting technology, solid construction, and ergonomic operation to deliver a powerful, professional solution for plastic processing.

It is the perfect choice for manufacturers seeking precise, safe, and cost-effective cutting of PVC and plastic profiles.

Whether in window, door, or façade production, this machine ensures consistent quality and efficiency in industrial applications.

Contact our team for a free consultation or personalized quotation: Click here

English

English

German

German

French

French

Spanish

Spanish

Portuguese

Portuguese

Italian

Italian

Polish

Polish

Turkish

Turkish

Romanian

Romanian

Greek

Greek

Bulgarian

Bulgarian

Russian

Russian

Arabic

Arabic

Hindi

Hindi