SPECIAL MACHINE ENGINEERING

Special Machine Engineering by Evomatec – Innovation, Precision, and Individuality in Mechanical and Plant Engineering

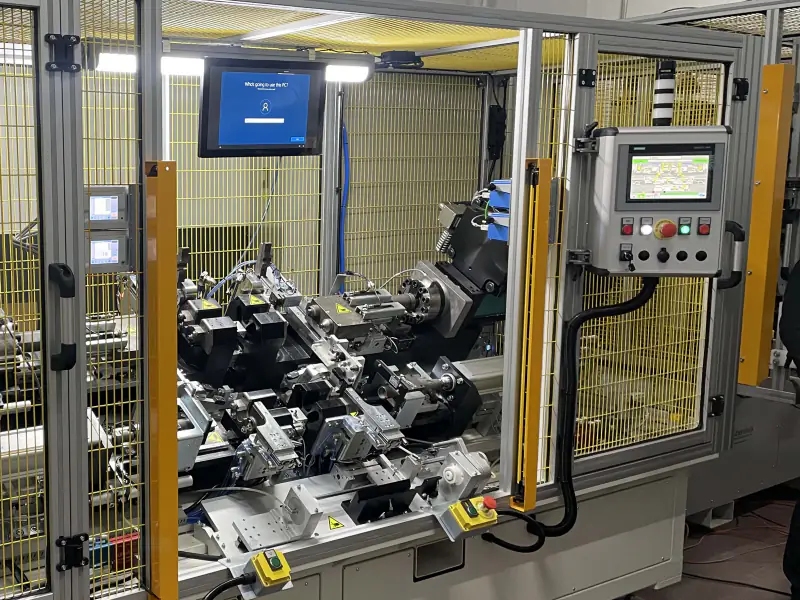

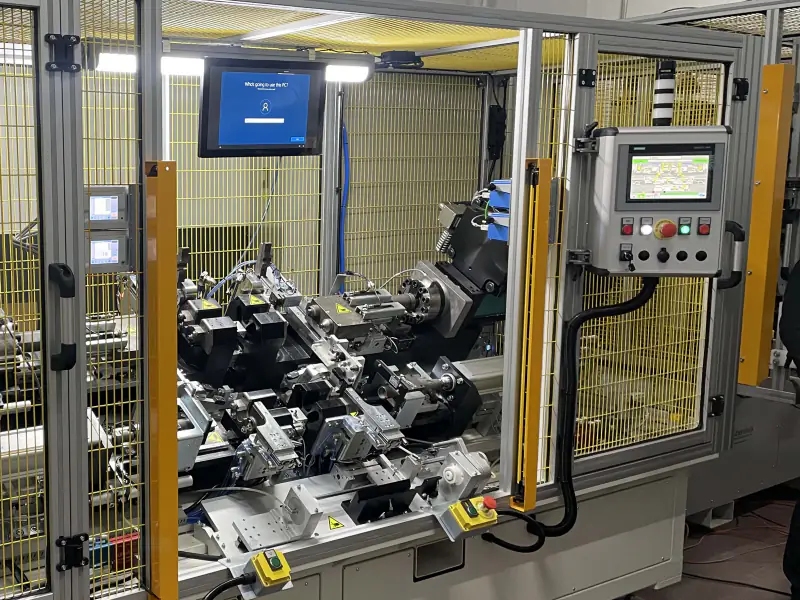

Evomatec Special Machine Engineering – Tailor-Made Solutions for Industrial Perfection

At the core of modern mechanical and plant engineering lies special machine construction – the art of combining technological precision with customized functionality.

Evomatec designs and manufactures special machines, customized systems, and automation solutions that are precisely tailored to each client’s production requirements.

With decades of expertise in manufacturing technology, automation, robotics, and digital control systems, Evomatec ranks among the leading providers in the field of special-purpose machinery – from concept development to turnkey commissioning.

Why Choose Special Machine Engineering from Evomatec?

Conventional mechanical engineering reaches its limits when standard solutions no longer suffice. This is where Evomatec’s special machine engineering begins:

Where standard machines end, Evomatec creates individual machine solutions – perfectly adapted to the product, process, and production environment.

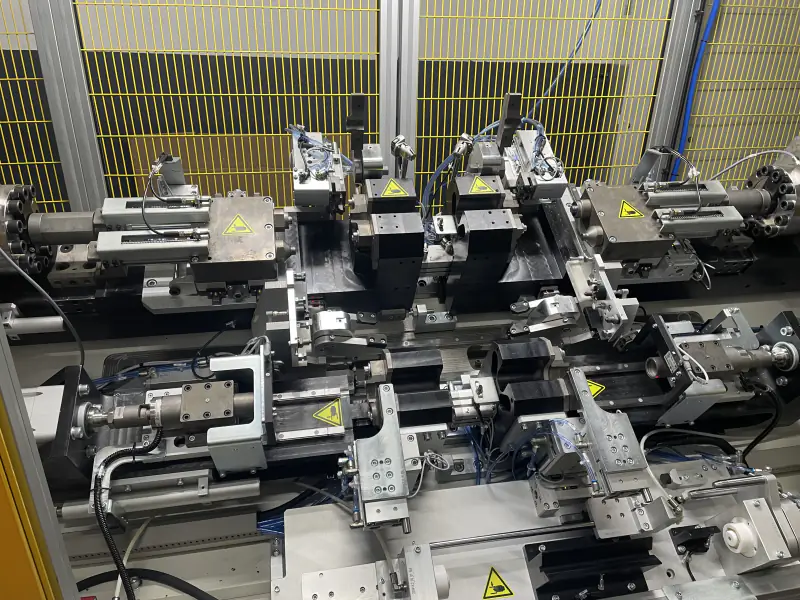

Every special machine is the result of engineering excellence, innovation, and customer-oriented design. Evomatec combines craftsmanship precision with cutting-edge CAD design, CNC manufacturing, hydraulics, pneumatics, and intelligent control systems.

Special Machine Engineering as the Key to Efficiency

Custom Machines and Industrial Systems

Evomatec develops single-unit and small-series machines designed specifically for the customer’s production processes.

Whether in the automotive industry, medical technology, food processing, or packaging, each custom system is based on detailed process analysis and defined performance parameters.

The result: maximum productivity, process reliability, and energy-efficient operation at the highest level of quality.

Special Plant Engineering for Complex Production Processes

Evomatec’s special plant engineering stands for efficiency in motion.

From assembly lines, dosing and filling systems, to handling and packaging systems, Evomatec designs and implements complete production plants with outstanding precision.

Thanks to modular design, systems can be expanded, adapted, or integrated into existing production environments with ease.

Engineering and Concept Development in Special Machine Construction

Every special machine begins with an idea – and ends as a fully automated system.

Evomatec supports its clients from the initial concept to final delivery:

Needs Analysis & Consulting – identification of all technical and economic requirements

Concept Development – creation of CAD models, simulations, and feasibility studies

Engineering & CAD Design – 3D modeling, stress tests, and motion analysis

Prototyping & CNC Manufacturing – precise production of customized components

Assembly & Commissioning On-Site – turnkey installation and start-up

Service, Maintenance & Retrofit – long-term support and modernization

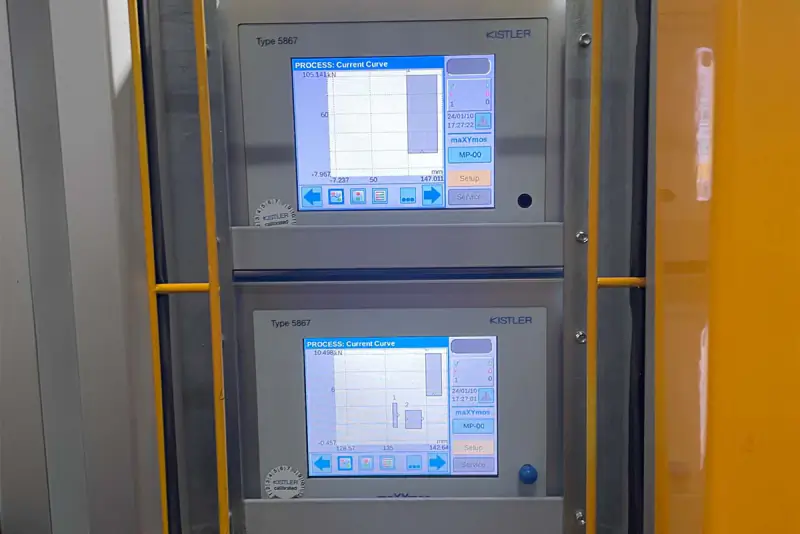

Each Evomatec machine undergoes a strict quality process that guarantees safety, performance, and reliability.

Special Machine Engineering for Key Industries

Automotive Industry

Evomatec develops special-purpose machines for the automotive sector, offering maximum precision and high cycle rates – such as assembly systems for body components, aluminum profile processing, and bonding systems for composite materials.

The integration of robotics, PLC control, and machine vision systems ensures exact positioning and intelligent quality inspection.

Food Industry

The food industry demands hygienic design, easy cleaning, and robust operation.

Evomatec builds dosing and filling systems, conveyors, and packaging machines made from stainless steel, compliant with international hygiene standards.

These systems feature intuitive controls, quick setup, and low-maintenance design for continuous production efficiency.

Pharmaceutical and Medical Technology

In the medical and pharmaceutical sectors, Evomatec provides custom systems for sterile manufacturing environments.

Solutions include automation cells, assembly systems, and testing machines with cleanroom certification, full traceability, and integrated digital documentation.

Packaging Industry

For packaging operations, Evomatec engineers special machines for cartoning, labeling, sealing, and palletizing.

Combining robotic handling, sensor technology, and automation software, these systems enable rapid format changes, short setup times, and increased throughput.

Metal, Plastic, and Rubber Industries

In metal and plastic processing, Evomatec’s special machines represent precision and durability.

Whether CNC-based, hydraulic, or pneumatic, each system is built for maximum load capacity, repeat accuracy, and process safety under industrial conditions.

Automation, Robotics, and Control Systems

Evomatec integrates automation technologyectly into every special machine solution.

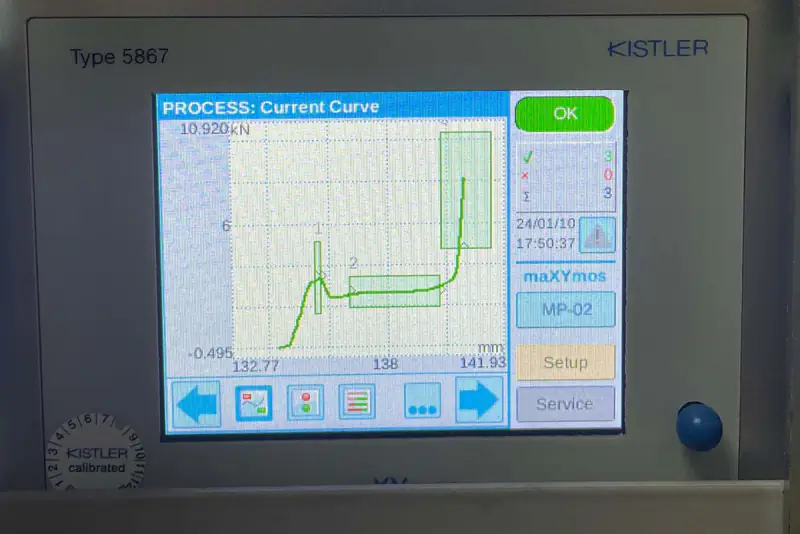

From PLC control to robotics and vision systems, each Evomatec installation features intelligent control software that monitors and optimizes processes in real time.

Key automation solutions include:

Process Automation with adaptive sensor technology

Robotics Integration with Cobots, Articulated Robots, and Delta Robots

PLC Systems (Siemens, Mitsubishi, FANUC, Beckhoff)

Vision Systems for optical inspection and quality assurance

Turnkey Special Machines – including software, installation, and training

These technologies create connected production ecosystems that merge human expertise, machine precision, and digital intelligence into a single system.

Turnkey Special Systems – Evomatec Turn-Key Engineering

Evomatec delivers complete turnkey machines – from concept to on-site commissioning.

Clients benefit from a single point of contact, a defined project timeline, and a guaranteed performance package.

All mechanical, electrical, and software components are internally tested, verified, and documented prior to installation.

This all-in-one philosophy ensures seamless project execution, including control systems, assembly, commissioning, and maintenance, resulting in faster, more efficient, and lower-risk implementation.

CAD Design and Digital Development

Evomatec’s design process relies on state-of-the-art CAD and CAE tools.

Each component, motion, and load scenario is digitally simulated to ensure optimal performance and efficiency.

The use of parametric 3D modeling allows easy future modifications and upgrades, supporting the full product lifecycle from prototype to production.

Retrofit and Modernization of Existing Systems

Instead of replacing old machines, Evomatec offers comprehensive retrofit programs.

By integrating modern control systems, smart sensors, and energy-efficient drives, older machines are upgraded to the latest industrial standards.

This modernization approach extends machine life, reduces operating costs, and minimizes downtime – a sustainable solution valued by Evomatec clients worldwide.

Assembly, Commissioning, and After-Sales Service

Evomatec’s experienced service engineers handle installation and commissioning with precision and attention to detail.

All machine functions, controls, and safety features are tested before handover.

Operator and maintenance training ensures safe and efficient use of every machine.

A global service network provides regular maintenance, spare parts, and rapid assistance whenever required.

Special Machine Engineering and Digitalization – The Future of Industry

Modern special machine engineering is evolving towards digital manufacturing.

Evomatec integrates sensors, cloud data, AI analytics, and machine learning into its systems.

Each machine becomes an intelligent, networked production unit that can evaluate data, detect errors, and automatically optimize parameters.

This fusion of engineering excellence and digital innovation defines the next generation of Industry 4.0 solutions – boosting efficiency, transparency, and competitiveness.

Evomatec – Your Partner for Custom Special Machine Engineering

Evomatec stands for technology, quality, and reliability in special-purpose machinery.

From design and production to commissioning, the company offers holistic engineering expertise and end-to-end solutions.

Every Evomatec machine is built with unmatched precision, CE compliance, and international quality certification – designed for decades of operation.

Evomatec combines German engineering with global innovation power, delivering custom-built production systems that shape the future of industrial manufacturing.

Contact our sales team: info@evomatec.de

English

English

German

German

French

French

Spanish

Spanish

Portuguese

Portuguese

Italian

Italian

Polish

Polish

Turkish

Turkish

Romanian

Romanian

Greek

Greek

Bulgarian

Bulgarian

Russian

Russian

Arabic

Arabic

Hindi

Hindi