ABB ROBOTS FOR GLASS PROCESSING

ABB Robots for Glass Processing: Automation Solutions for Maximum Precision and Efficiency

Efficient ABB Robots Solutions for Glass Processing

Evomatec is your expert partner for the implementation of state-of-the-art ABB Robot systems specifically designed for glass processing. With over 50 years of experience in robotics and automation, we offer tailored solutions that optimize the entire glass processing workflow from glass milling to glass assembly. Our robots for glass processing provide not only exceptional precision but also remarkable flexibility, allowing you to process various types of glass efficiently and cost-effectively. Whether for flat glass processing, automotive window glass, or automotive windshields, we provide solutions that optimize your production processes and improve the quality of your glass products.

Our ABB Robot solutions are specifically tailored to meet the requirements of glass processing. They automate complex processes such as glass cutting, glass milling, glass drilling, and glass assembly. By using ABB robot cells for glass processing, we ensure seamless integration into existing production lines, boosting your productivity while minimizing error rates. The goal is to reduce manufacturing costs while maximizing the quality of the glass products.

Glass Processing Automation with ABB Robot Systems

Glass processing automation is a crucial element in modern manufacturing, playing a decisive in improving production speed and reducing errors. With ABB Robot systems, we provide a top-tier solution for optimizing your glass production. Flat glass processing robots, automotive window glass robots, and automotive windshield robots allow various processing steps to be executed precisely and automatically.

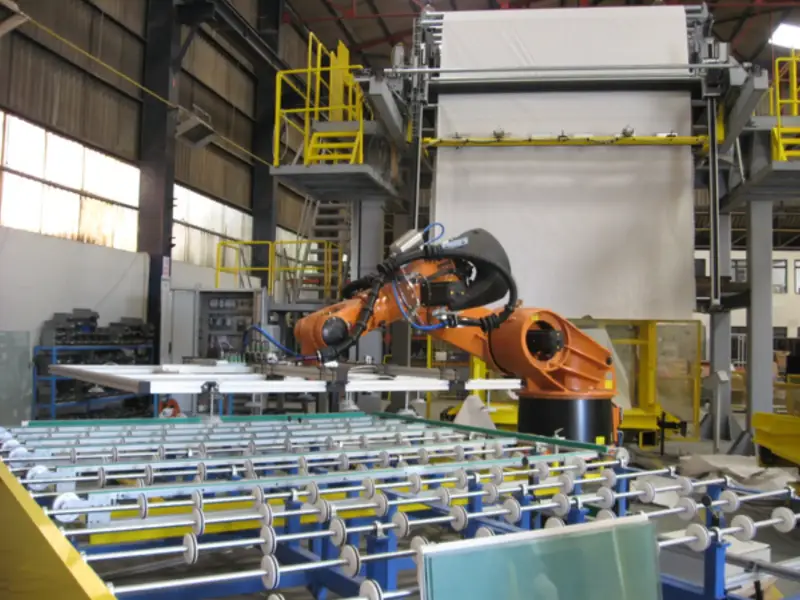

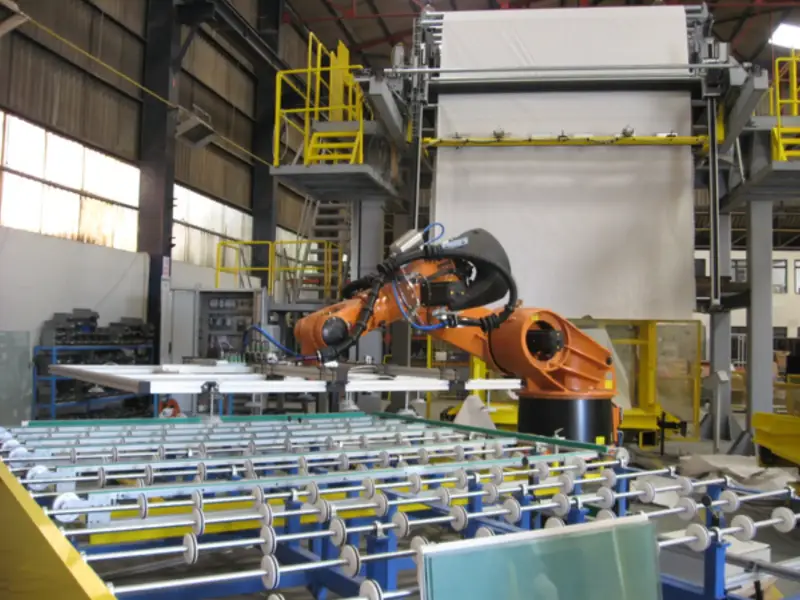

Our ABB robot cells for glass processing ensure efficient and safe glass sheet positioning and handling during various processing stages. The integration of automation in glass processing encompasses numerous processes such as glass cutting for flat glass and automotive glass, milling glass for precise edges, and drilling holes for assembly. With ABB robots, you can carry out these tasks with high repeatability and minimal waste.

ABB Robots for Flat Glass Processing: Precision for the Highest Demands

In flat glass processing, ABB robots are an indispensable solution to meet the growing demands of the industry. Flat glass processing involves several complex steps such as glass cutting, glass milling, and polishing of glass surfaces. Our robots for flat glass processing offer not only high precision in CNC glass processing, but also innovative vacuum technology for glass, ensuring safe handling throughout the entire processing cycle.

These flat glass robot solutions are perfect for glass cutting as they precisely position glass panels and cut them accurately. At the same time, they guarantee high speed and low error rates, allowing you to achieve optimal quality in your flat glass products while reducing production time.

ABB Robots for Automotive Glass Manufacturing: Automation in Vehicle Glazing

Automotive glass manufacturing presents special requirements for glass processing. ABB robots offer a customized solution for glass cutting and the assembly of windshields and automotive windows. Our robots for automotive windshields and robots for automotive window glazing allow for precise cutting of automotive glass and safe integration into the vehicle frame. The use of vacuum grippers for automotive windows ensures reliable handling of the glass during the entire processing cycle.

Installing windshields in vehicles requires utmost precision, and our ABB robots for windshield installation in vehicles ensure that the automotive window installation is performed with the highest accuracy. Our solutions also include the integration of robot cells for glass processing used in automotive glass manufacturing to automate and optimize the entire process.

Robots for Glass Assembly and Glass Transport: Efficiency in Glass Production

Another critical area in glass processing is glass assembly. ABB robots for glass assembly are used to efficiently assemble glass products such as windows, doors, and automotive glass into production lines. Our robots for glass assembly are equipped with advanced vacuum grippers for glass that allow for precise handling and positioning of glass sheets.

Robots for glass transport also play a decisive as they handle the transportation of glass between various production steps. With robots with glass handling equipment, we can move glass sheets from one processing area to the next, boosting productivity and minimizing material loss.

After-Sales Service for Your ABB Robot Solutions

Evomatec offers not only robot installation and robot programming, but also comprehensive after-sales service to ensure that your ABB robots for glass processing are always operating optimally. We provide regular maintenance services, software updates, and troubleshooting to ensure that your ABB robot cells for glass processing stay in top condition.

Our after-sales services include the inspection of robot control systems and the adjustment of robot cells for glass processing to meet the latest production requirements. We offer tailored maintenance plans specifically designed for your glass processing production, ensuring that your ABB robots are always working efficiently.

Long-Term Partnership for Your Glass Processing Production

With Evomatec, you have a long-term partner by your side who will support you throughout the entire lifecycle of your ABB robots. From the initial concept to CNC glass processing and the implementation of robot systems for glass processing, we provide everything you need for a successful automation of your glass production. Our customer service department ensures that your robot cells for glass processing remain in top condition and continuously improve your production efficiency.

Contact our sales team: info@evomatec.de

English

English

German

German

French

French

Spanish

Spanish

Portuguese

Portuguese

Italian

Italian

Polish

Polish

Turkish

Turkish

Romanian

Romanian

Greek

Greek

Bulgarian

Bulgarian

Russian

Russian

Arabic

Arabic

Hindi

Hindi